In today’s operational landscape, where precision and speed drive outcomes, most businesses are already tracking their assets. GPS, RTLS, BLE, UWB — the technologies are there. Dashboards are active. Maps are live. But something’s still missing.

You know where everything is.

But do you know what everything is doing?

And more importantly — what should happen next?

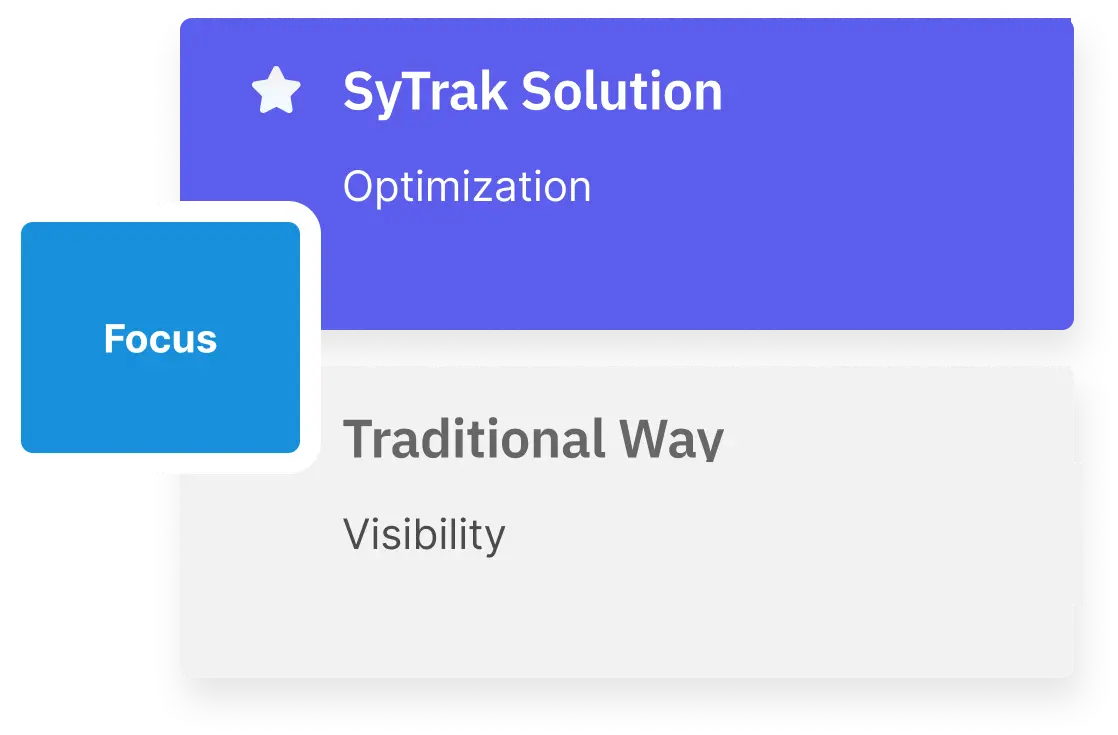

This is the gap between visibility and control.

And closing it is what orchestration is all about.

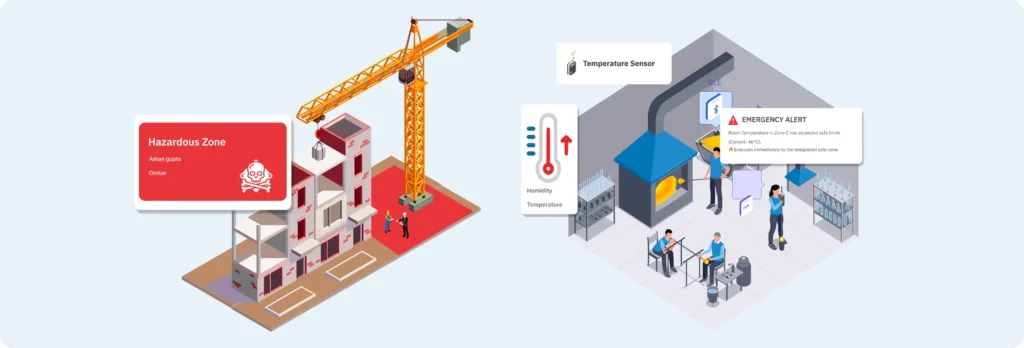

Let’s say you manage a manufacturing facility, a hospital, or a fleet yard. At any given time, hundreds of physical assets — machines, tools, containers, devices — are in motion. Some are working. Some are idle. Some are being misused. Some are simply… missing. Now imagine:

All of this is trackable — but not necessarily manageable. What businesses need is not just tracking technology, but an intelligent control system that reads this complexity and turns it into coordinated, real-time action.

Industrial Asset Orchestration is the ability to not only observe asset activity, but to coordinate it intelligently across environments.

It brings together:

In simpler terms:

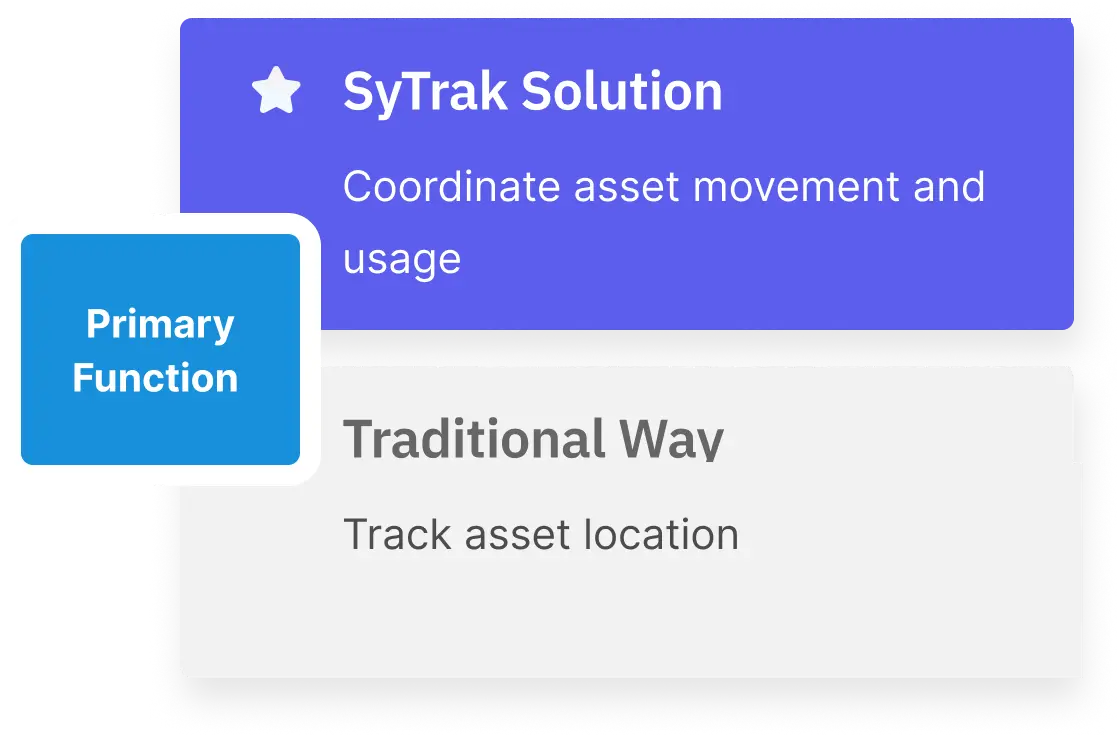

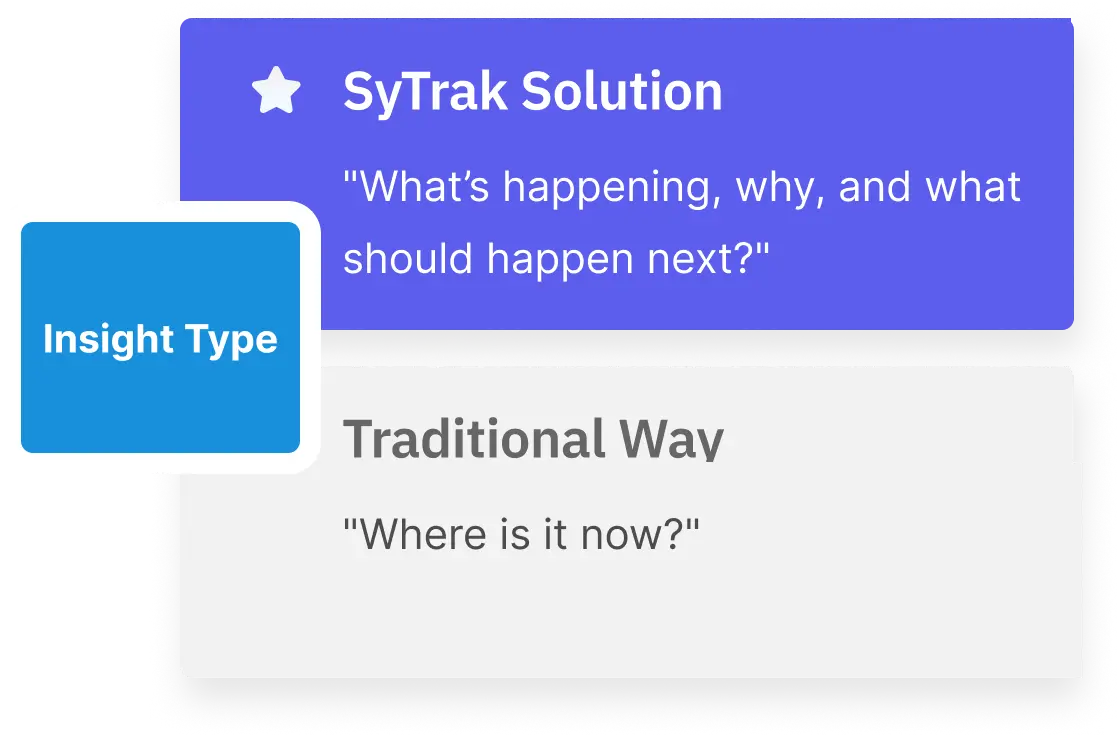

While traditional systems answer “Where is my asset?”

Orchestration asks “Is it where it should be — and doing what it’s supposed to?”

And then helps resolve it in real time.

This shift aligns with the broader goals of industry 4.0, where operational technologies are expected to move from passive reporting to intelligent response and self-optimization.

Think of orchestration as an operating system for physical workflows, built on five key layers:

Take a large logistics hub:

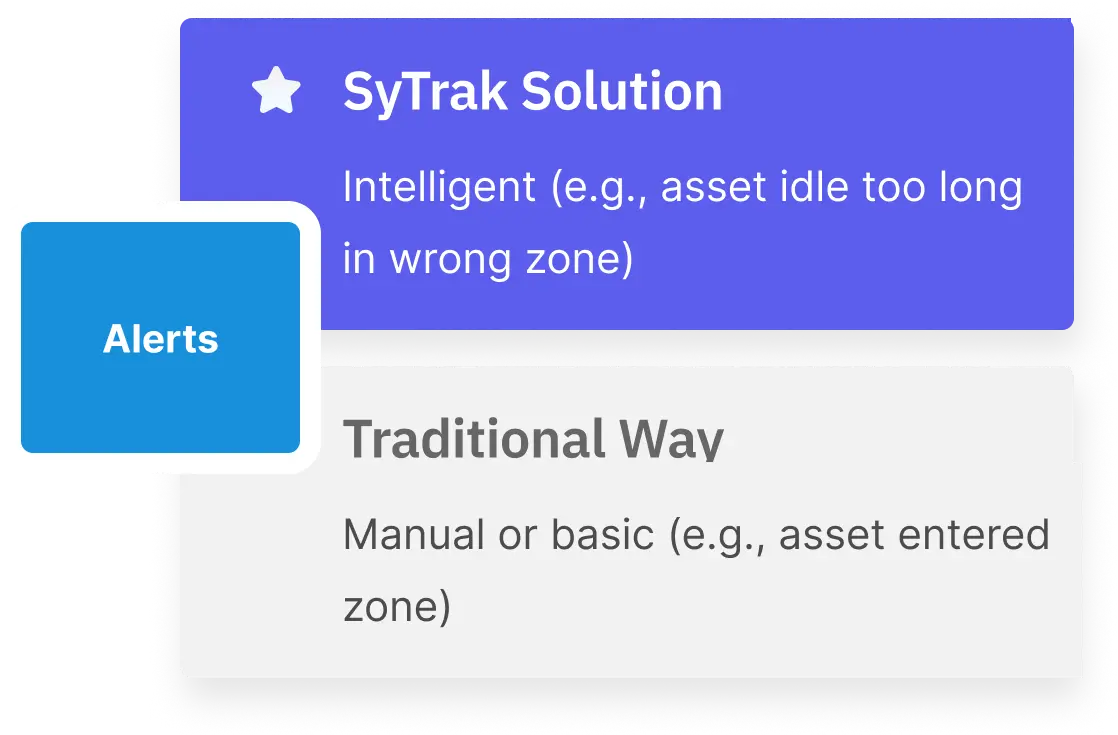

In a standard Asset Tracking System, this may get flagged too late. But in an Industrial IoT Platform designed for orchestration:

This is Real-time Asset Tracking, with context and coordination.

This is Smart Asset Management.

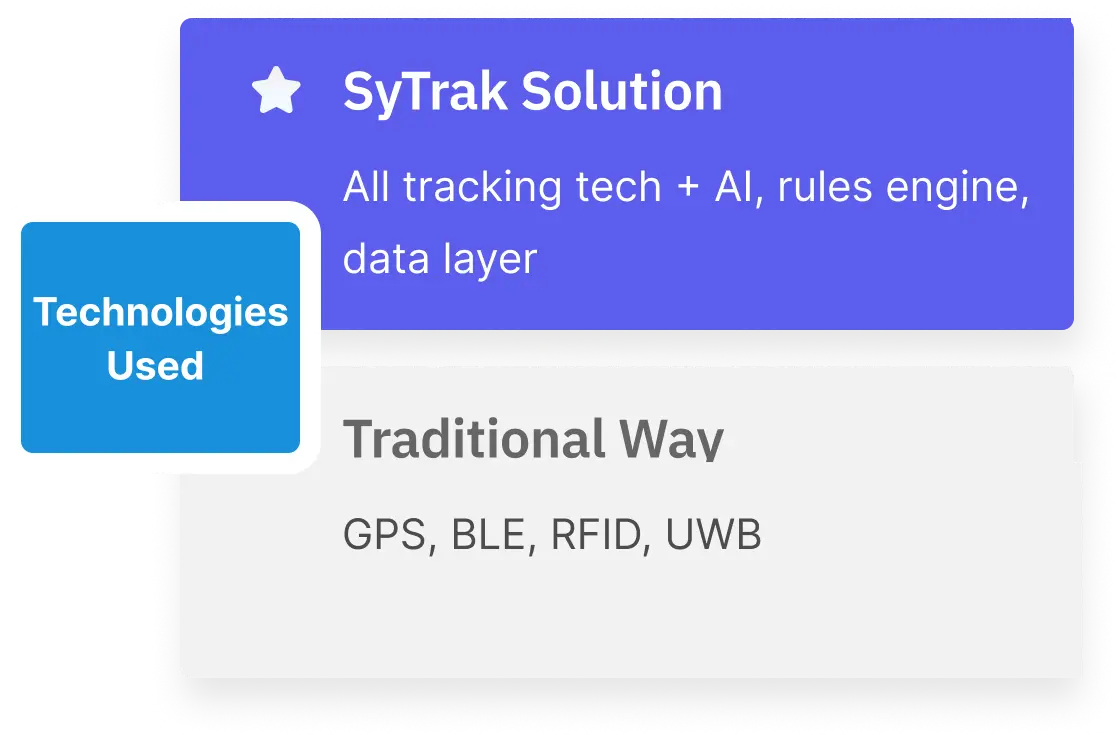

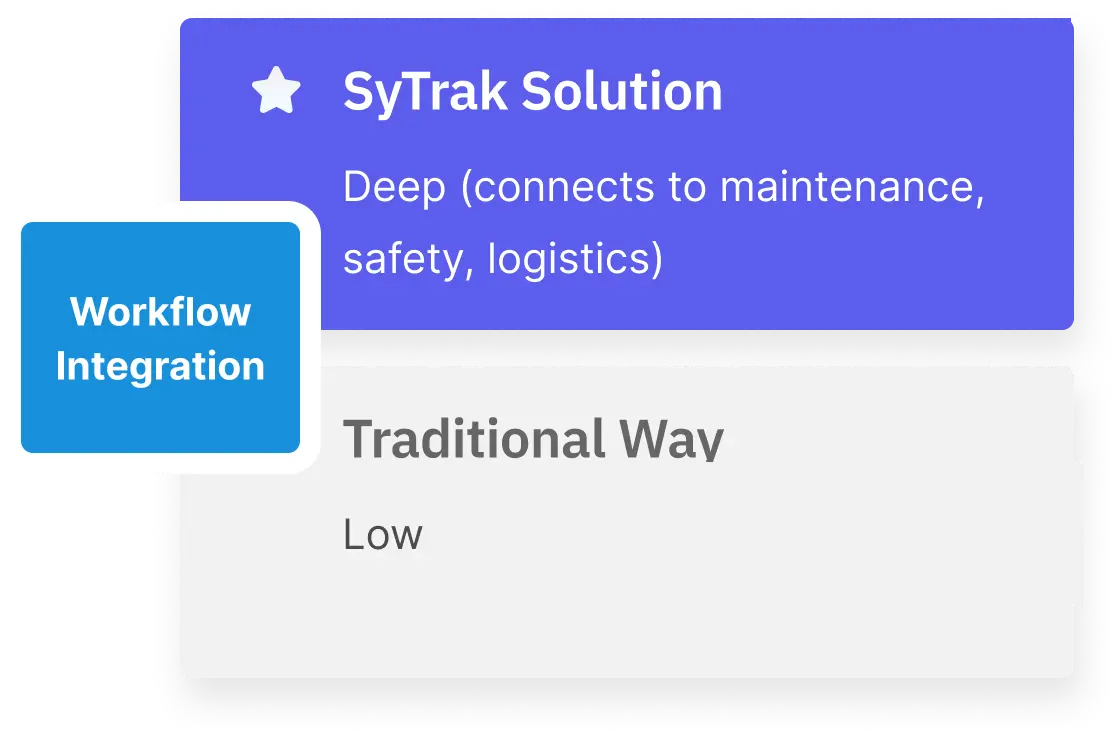

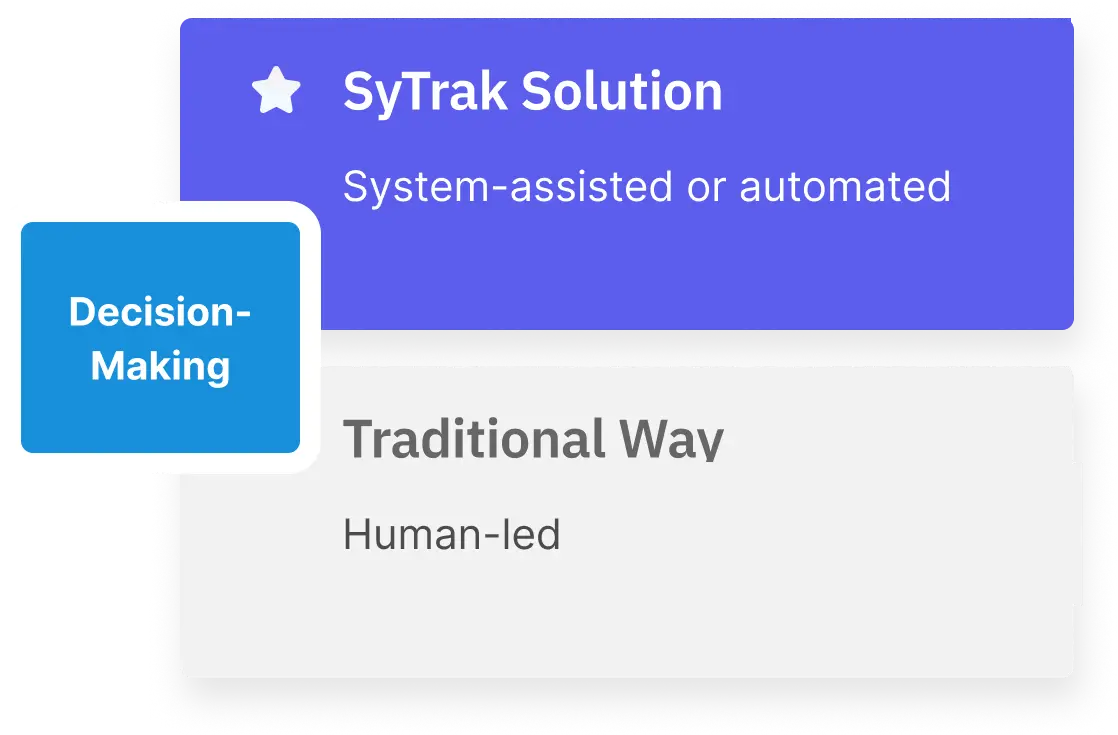

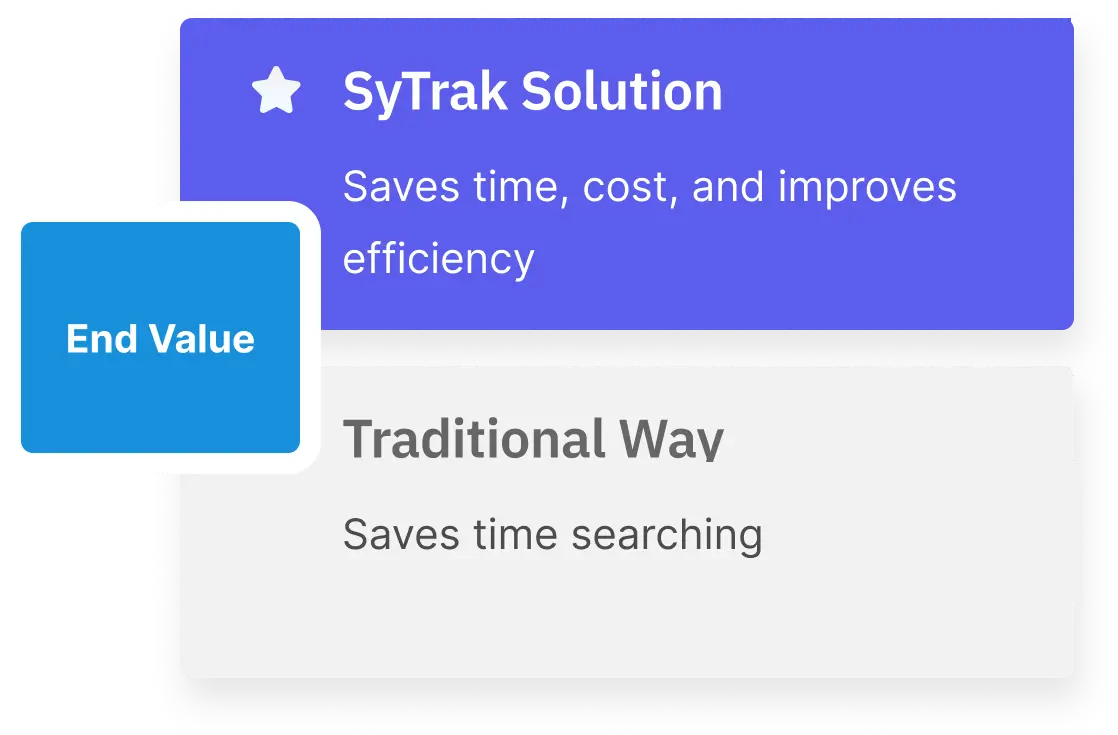

Here’s a clear breakdown:

SYTRAK goes far beyond conventional tracking. It’s a next-generation Industrial IoT Platform that enables businesses to orchestrate their operations — not just monitor them.

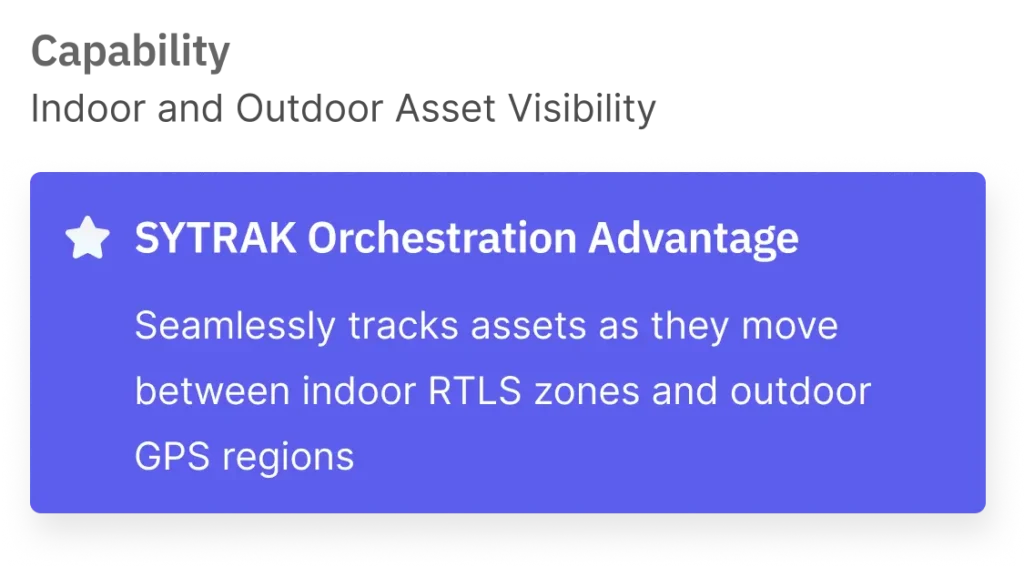

Here’s how SYTRAK delivers true Industrial Asset Orchestration:

SYTRAK doesn’t just show where things are.

It tells you what to do about it.

In the context of Industry 4.0, orchestration is a critical enabler of smart operations. It connects the dots between:

SYTRAK is built to sit at the heart of this transformation — empowering manufacturers, logistics providers, healthcare systems, and field operations to orchestrate with intelligence and act with precision.

From Tracking to Orchestrating — The Evolution Has Begun

What started as simple asset tracking has matured into a powerful layer of operational coordination.

SYTRAK helps you move:

Because in complex operations, every minute matters, every asset counts, and every decision should be data-backed.

Manufacturing is a high-speed, high-stakes environment where multiple production lines operate at once. Machines, tools, materials, and workers must stay in sync for peak efficiency. With SYTRAK, manufacturers gain precise, real-time tracking of every moving part, reducing downtime, ensuring safety, and maintaining throughput in even the most complex industrial setups.

In an increasingly connected world, knowing where your assets are—and keeping them secure—is more critical than ever. Whether it’s a shipment in transit, a safety kit in a hospital, or a tool in a factory, SYTRAK ensures location intelligence with real-time visibility, helping industries respond faster, reduce risks, and stay in control.

In today’s fast-paced Industry 4.0 landscape, companies can’t afford slow or disconnected asset management. From forklifts in warehouses to medical equipment in hospitals and machinery on construction sites, real-time visibility is essential. SYTRAK enables smarter tracking, monitoring, and decision-making to keep workflows agile, efficient, and secure across industries.

Our website use cookies. By continuing navigating, we assume your permission to deploy cookies as detailed in our Privacy Policy.