In 2025, operational resilience has become the most discussed theme across manufacturing, logistics, and supply chain forums. From global disruptions to workforce variability and rising customer expectations, companies are racing to strengthen their ability to anticipate, absorb, and adapt to disruptions not merely react to them.

And at the center of this transformation lies one critical layer:

Visibility has moved from “nice to have” to “business survival.”

Trending reports from Industry 4.0 leaders show that organizations with real-time operational intelligence outperform peers in :

The reason? If you can’t see what’s happening on your shop floor or facility — you can’t control it, optimize it, or scale it.

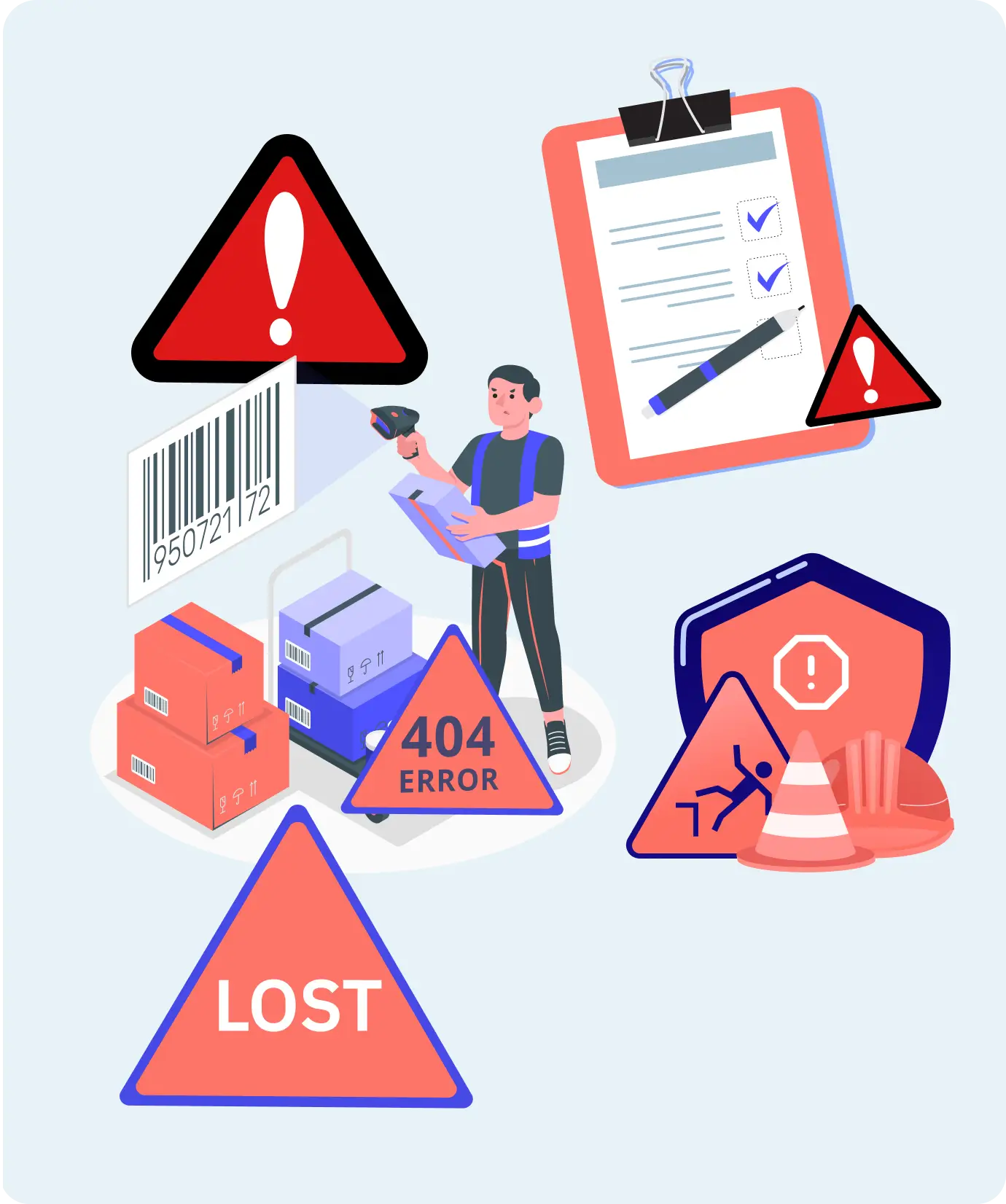

Even in 2025, many companies are stuck with :

This creates what experts call the Visibility Gap — the disconnect between operations happening in real time and the information available to decision-makers.This gap leads to inefficiency, downtime, asset loss, bottlenecks, and poor customer experience.

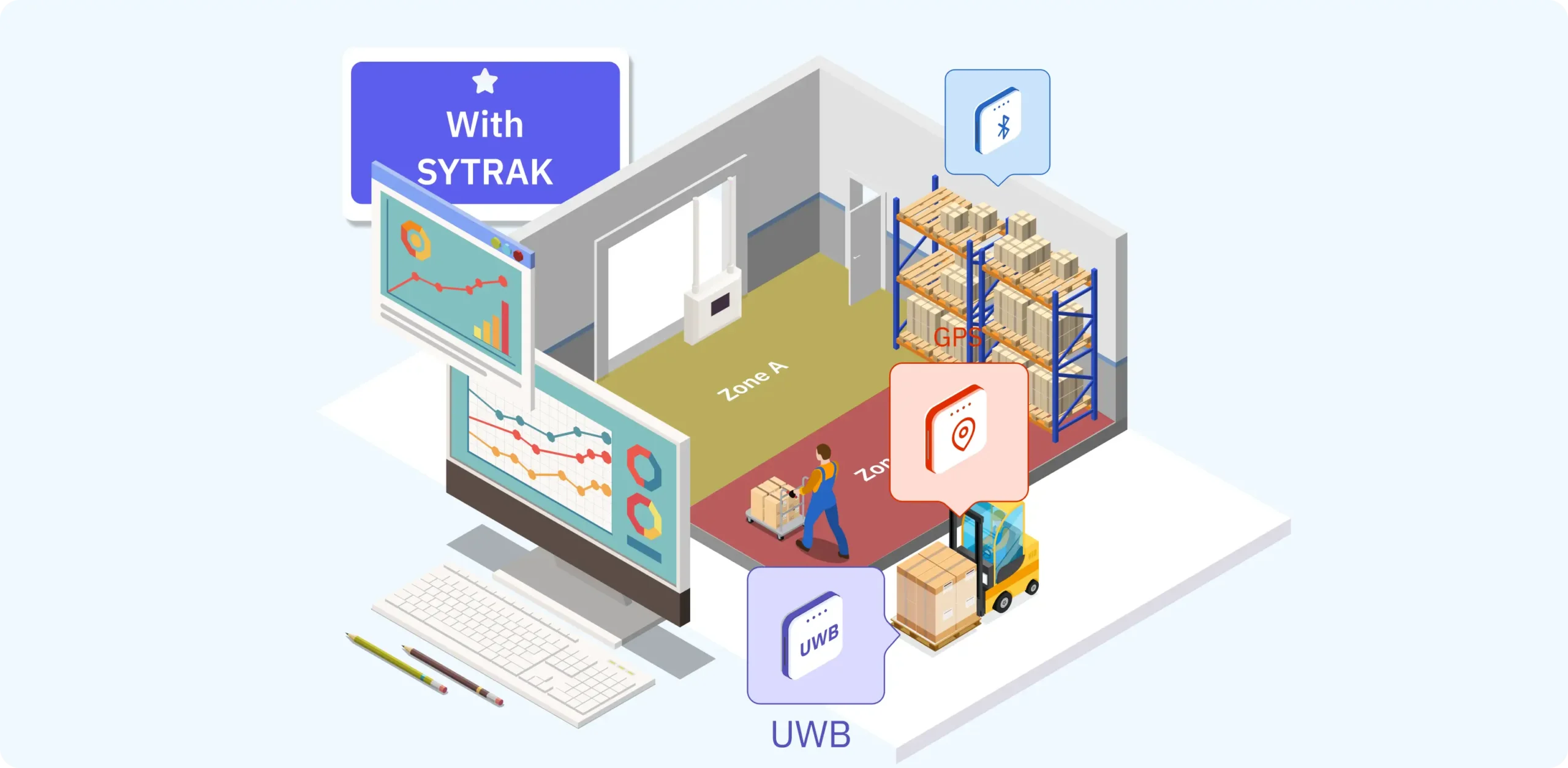

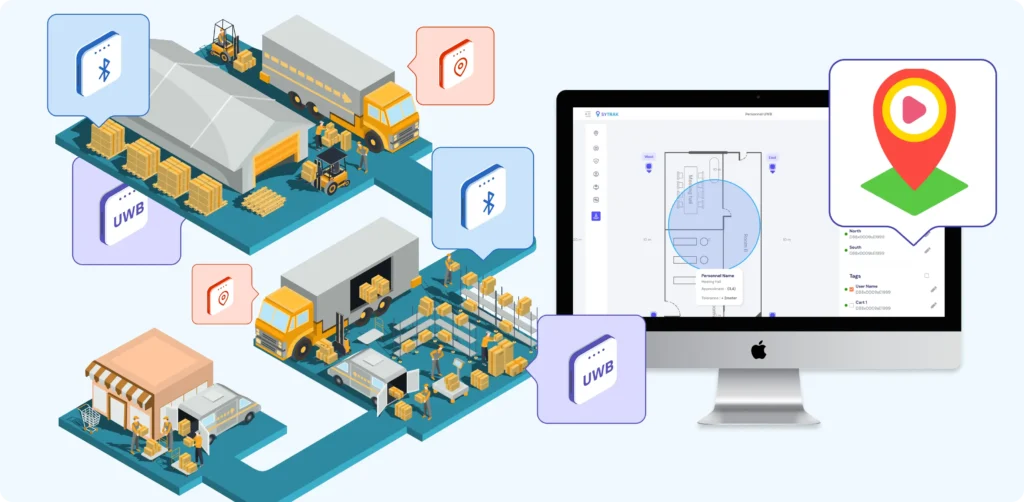

SYTRAK closes this visibility gap by delivering real-time, indoor-outdoor asset intelligence through an integrated hardware + software orchestration platform.

Track assets, tools, equipment, and personnel with precision — across indoor facilities, yards, and distributed field environments.

No blind spots. No delays. Just truth, live.

SYTRAK uses movement patterns, utility trends, and workflow data to help teams:

This aligns perfectly with the 2025 shift toward proactive operations, not reactive firefighting.

With increasing concerns about data breaches and equipment theft, SYTRAK’s tamper alerts and encrypted communication offer peace of mind and compliance.

Whether it’s manufacturing, logistics, healthcare, construction, or automotive — SYTRAK adapts to your facility, your assets, and your workflow.

You don’t adapt to SYTRAK. SYTRAK adapts to you.

SYTRAK’s tamper detection and audit trails help organizations stay compliant without extra effort.

As operational resilience becomes the most important trend of 2025, companies across sectors are embracing systems that give them truth, clarity, and control. SYTRAK doesn’t just show you where things are. It helps you know what’s happening, understand why it’s happening, and orchestrate operations accordingly.

In other words:

SYTRAK helps you know where it is now — and what to do next.

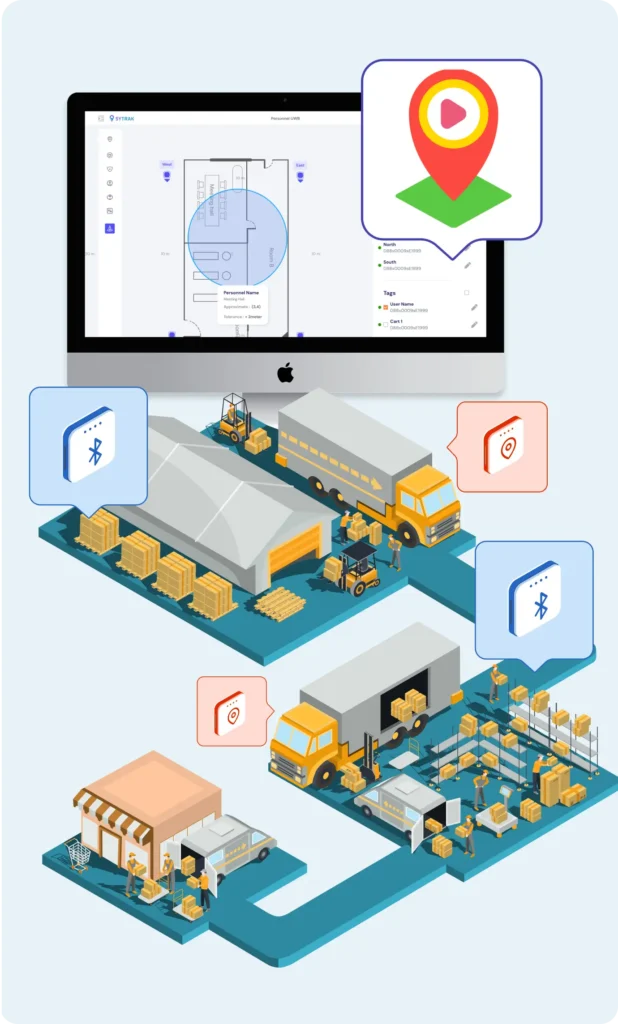

In today’s fast-moving industrial world, simply knowing where assets are is no longer enough. What matters is understanding their context, purpose, and next step. SYTRAK delivers true orchestration by combining location data with analytics and predictive intelligence, turning visibility into active control. The result: smarter workflows, greater efficiency, and proactive operations.

As industries evolve under Industry 4.0, asset tracking must deliver more than dots on a map. SYTRAK transforms tracking into orchestration, enabling safer, smarter, and more efficient operations. With contextual insights, intelligent coordination, and automation, SYTRAK empowers organizations to streamline workflows, reduce risks, and adapt quickly in even the most complex industrial environments.

In a fast-paced, data-driven economy, real-time asset tracking is no longer optional — it’s essential. SYTRAK ensures you know where your tools, shipments, or equipment are at all times, while also delivering insights that reduce downtime, minimize losses, and boost productivity. Whether in hospitals, factories, or logistics, SYTRAK keeps critical operations secure and reliable.

Our website use cookies. By continuing navigating, we assume your permission to deploy cookies as detailed in our Privacy Policy.