In 2025, operations across manufacturing, logistics, warehousing, healthcare, and construction are undergoing a fundamental shift. What was once a collection of isolated processes and disconnected systems is rapidly evolving into a unified ecosystem of connected, intelligent, real-time operations. Organizations are moving beyond automation alone they now demand visibility, orchestration, and data-driven predictability.

At the center of this transformation lies one critical enabler:

Real-time visibility across people, assets, workflows, and environments.

And this is exactly where SYTRAK stands out.

Global industry reports highlight a clear trend: companies with integrated, data-connected systems outperform their counterparts in productivity, resilience, and cost efficiency. Modern operations no longer rely on manual tracking, spreadsheets, or reactive firefighting. Instead, they require:

This shift towards “connected operations” is not optional — it is becoming the competitive differentiator of 2025.

Even today, most operational delays and inefficiencies can be traced to one root cause:

Visibility failures — not system failures.

These micro-delays accumulate, creating:

Despite investing in automation and infrastructure, organizations still struggle with one basic question:

“Where is everything right now, and is it where it should be?”

SYTRAK answers this with precision.

SYTRAK bridges the visibility gap by offering a unified platform that brings location intelligence, workflow awareness, and predictive orchestration into a single system.

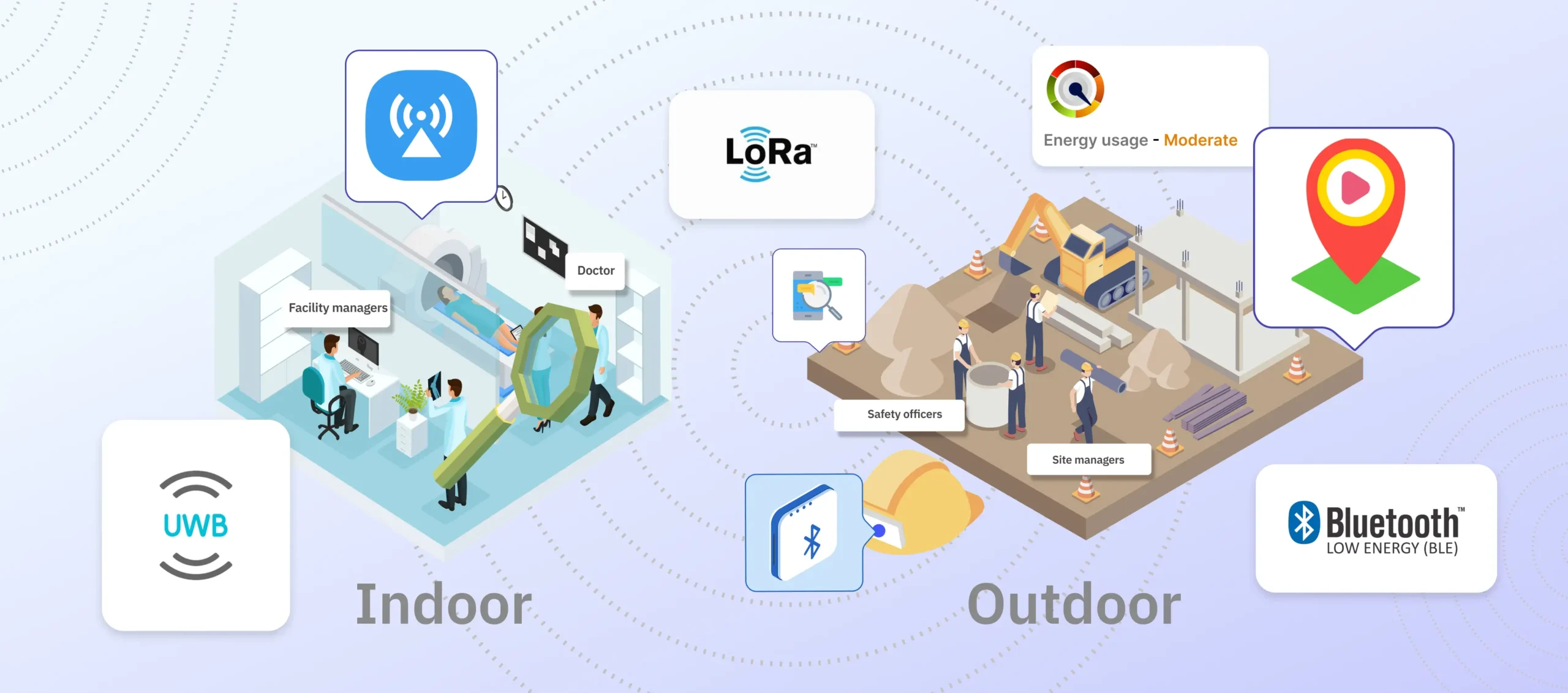

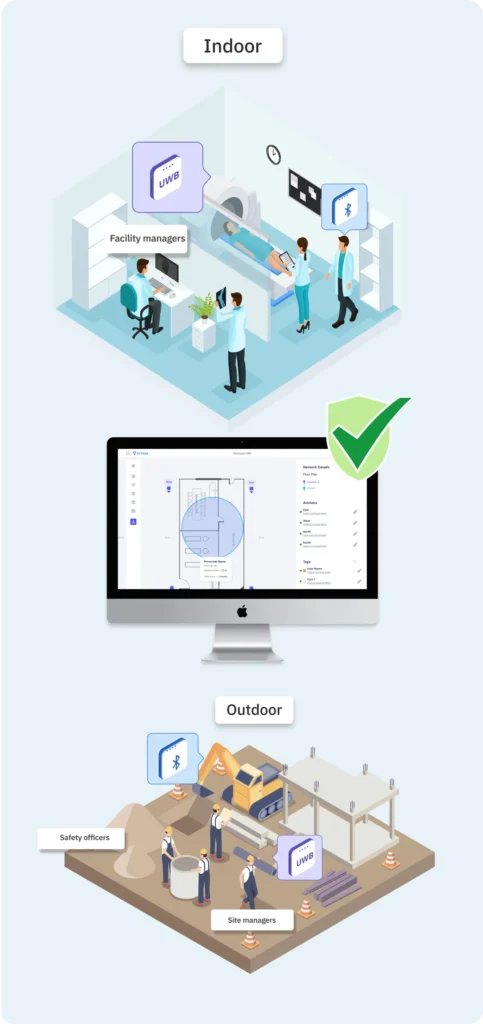

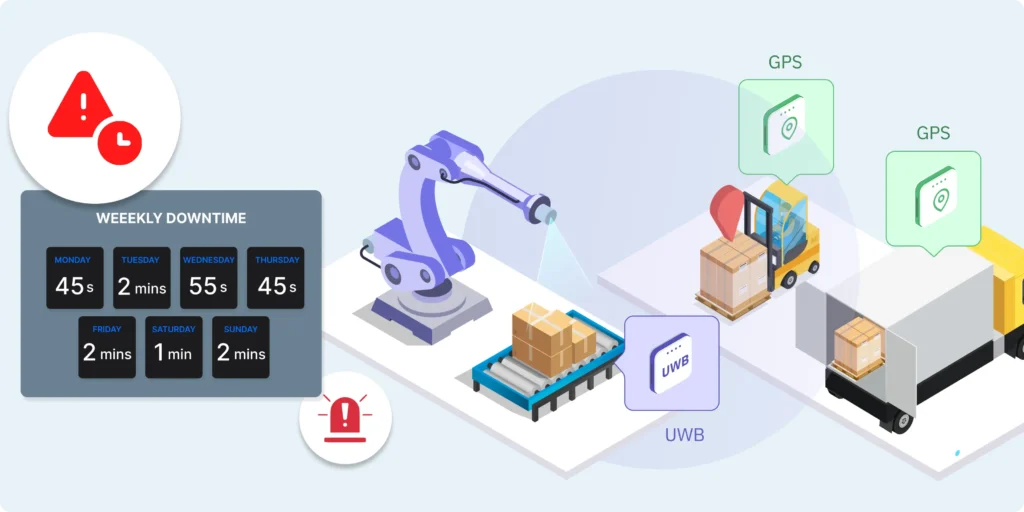

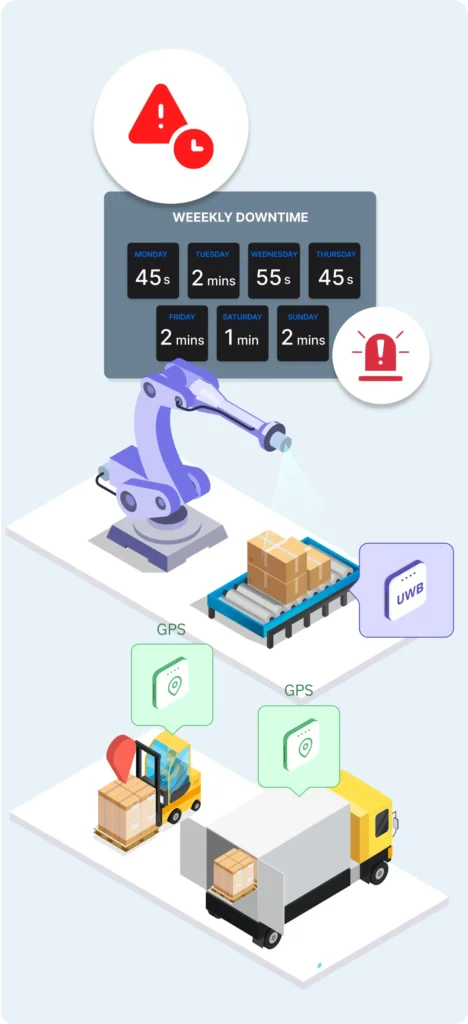

GPS alone is not enough. Indoor environments need precision tracking.

SYTRAK uses a hybrid of UWB, BLE, and intelligent sensors to track assets across any environment.

You can locate tools, trolleys, consumables, pallets, equipment, or vehicles in seconds — without blind spots.

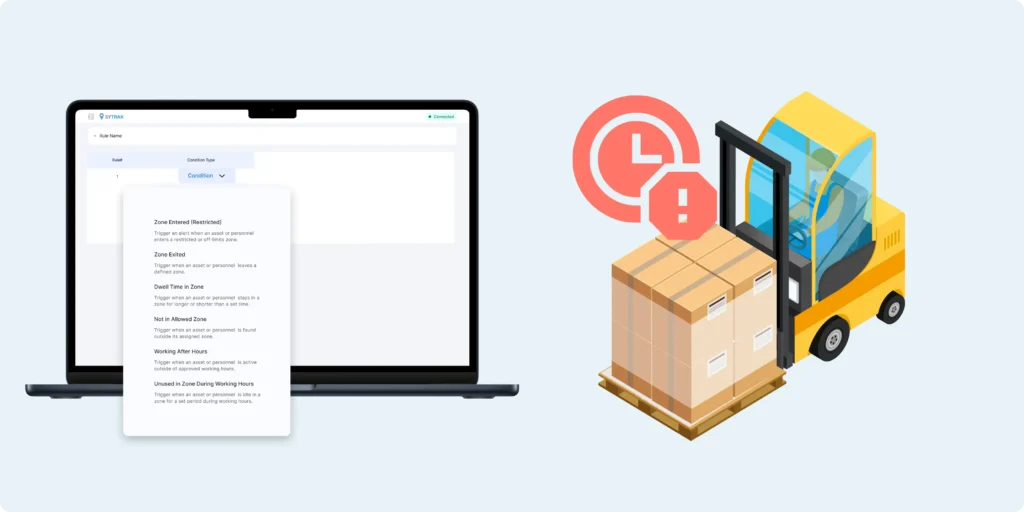

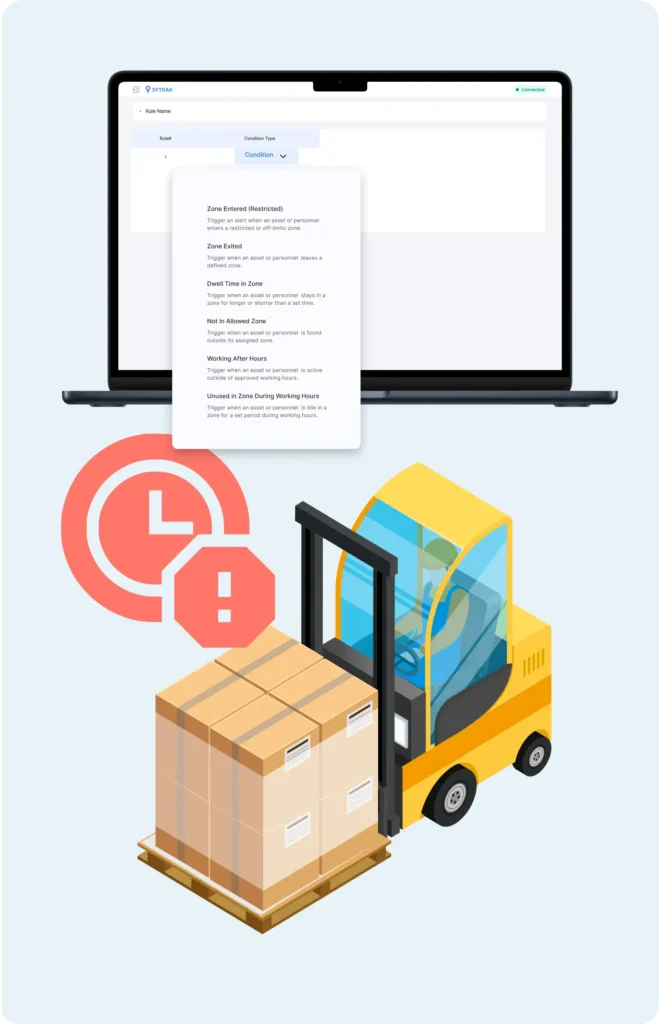

Unlike traditional tracking systems, SYTRAK understands process flow. If an asset deviates from expected movement or stays idle longer than the workflow requires, SYTRAK triggers real-time alerts.

Examples:

SYTRAK shifts teams from reactive to proactive operations.

By mapping time + location + workflow, it can detect delays before they impact production.

SYTRAK provides integrated insights:

These insights help teams eliminate recurring bottlenecks and continuously improve operations.

Before SYTRAK

After SYTRAK

This is what connected operations truly look like.

Industries in 2025 demand agility, efficiency, and resilience. SYTRAK delivers the critical components that modern operations now rely on:

When assets move with intelligence and workflows stay synchronized, organizations unlock a new level of operational performance.

SYTRAK doesn’t just tell you where things are — it tells you what happens next.

As industries grow more complex and expectations rise, connected operations will define the next decade of operational excellence. Companies that embrace this shift will reduce downtime, accelerate throughput, optimize resources, and respond faster to change.

SYTRAK is built for this future a future where operations are visible, predictable, and intelligently connected.

Know where it is now.

Know what comes next.

That’s the SYTRAK difference.

Our website use cookies. By continuing navigating, we assume your permission to deploy cookies as detailed in our Privacy Policy.