Mass manufacturing is a high-speed, high-stakes environment. Multiple production lines operate simultaneously, each with its own set of machines, tools, materials, and human resources. Keeping track of these moving parts is not just a logistical challenge — it’s a critical factor in maintaining operational efficiency, safety, and throughput.

SyTrak, the Industrial Asset Orchestration platform, is designed to address exactly this kind of complexity. By combining real-time asset tracking, RTLS (Real-Time Location Systems), smart asset management, and seamless workflow automation with your existing operational technologies, SyTrak ensures you always know where it is now — and can decide what happens next.

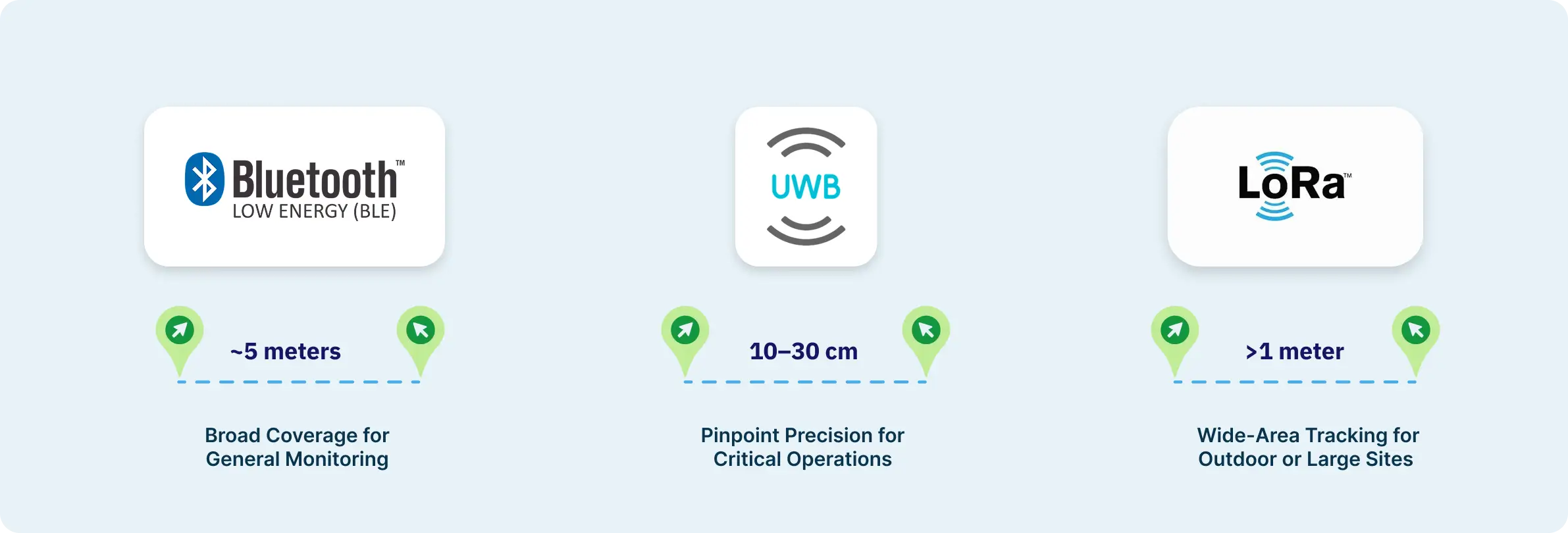

In a large manufacturing plant, there’s no one-size-fits-all tracking technology. Different zones have different accuracy needs, and SyTrak supports multiple location technologies to give you the right balance between precision, coverage, and cost.

Bluetooth Low Energy (BLE) — Broad Coverage for General Monitoring

Ultra-Wideband (UWB) — Pinpoint Precision for Critical Operations

LoRa — Wide-Area Tracking for Outdoor or Large Sites

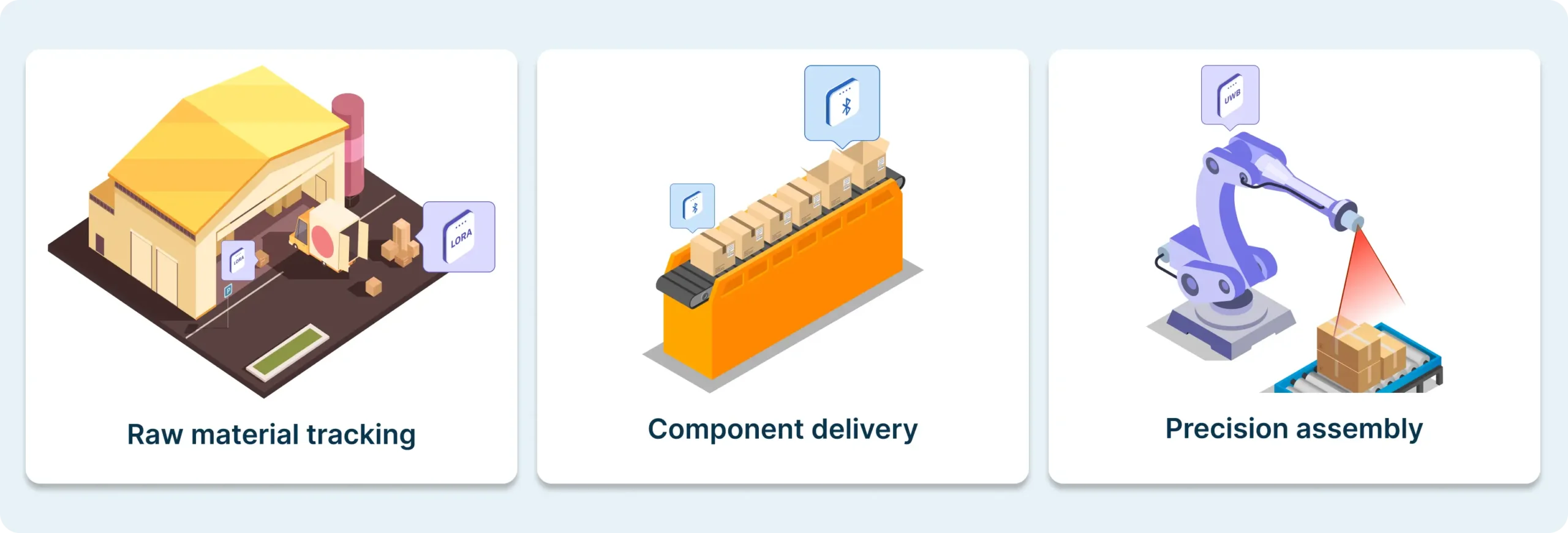

By combining these technologies into a layered RTLS tracking ecosystem, SyTrak delivers indoor and outdoor asset visibility — from precision assembly to outdoor logistics — ensuring the right accuracy, in the right place, at the right time.

Tracking data is only as valuable as the actions it enables. That’s why SyTrak integrates seamlessly with:

With SyTrak, you can trigger zone-based alerts and automation directly inside your current systems — no need to reinvent your IT stack, just make it smarter.

Imagine a facility with five parallel production lines, each producing different product variants:

This isn’t just tracking — it’s Industrial Asset Orchestration in action, turning location data into proactive asset management and intelligent decision-making.

This isn’t just tracking — it’s Industrial Asset Orchestration in action, turning location data into proactive asset management and intelligent decision-making.

In Industry 4.0 manufacturing, the difference between reacting and anticipating can mean millions in annual savings. With SyTrak’s combination of:

…manufacturers can move from a reactive stance (“Where is that tool?”) to a proactive one (“That tool will be needed in 5 minutes — send it to Line 3 now”). This shift improves operational efficiency, reduces downtime, and drives better resource allocation.

Whether you’re tracking hundreds of components or coordinating thousands of assets across multiple zones, SyTrak ensures every asset is managed intelligently. And because it works alongside your existing MES, ERP, and WMS systems, deployment is faster, training is simpler, and ROI is realized sooner.

In short, SyTrak doesn’t just track your assets — it orchestrates them.

Manufacturing has always been about precision, efficiency, and control. Yet, in today’s Industry 4.0 era, traditional methods are struggling to keep pace with the complexities of modern production. Manual logs, static shift plans, and disconnected systems create blind spots that cost factories valuable time and resources. .

In today’s fast-paced Industry 4.0 landscape, companies can’t afford slow or disconnected asset management. From forklifts in warehouses to medical equipment in hospitals and machinery on construction sites, real-time visibility is essential. SYTRAK enables smarter tracking, monitoring, and decision-making to keep workflows agile, efficient, and secure across industries.

In an increasingly connected world, knowing where your assets are—and keeping them secure—is more critical than ever. Whether it’s a shipment in transit, a safety kit in a hospital, or a tool in a factory, SYTRAK ensures location intelligence with real-time visibility, helping industries respond faster, reduce risks, and stay in control.

Our website use cookies. By continuing navigating, we assume your permission to deploy cookies as detailed in our Privacy Policy.