SyTrak RTLS Knowledge Hub:

Powering the Future of Operations

Explore expert articles on industrial IoT solutions, real-time asset tracking, geofencing, and digital orchestration. Learn how manufacturers, logistics providers, and infrastructure companies use SyTrak RTLS to boost visibility, streamline workflows, and reduce costs.

- December 31, 2025

As 2025 comes to a close, we at SYTRAK pause to reflect on a year defined by innovation, growth, and meaningful impact. Our mission to provide businesses with real-time, actionable asset visibility has guided every milestone, every product enhancement, and every customer success story this year.

- Dec 04, 2025

In 2025, operations across manufacturing, logistics, warehousing, healthcare, and construction are undergoing a fundamental shift. What was once a collection of isolated processes and disconnected systems is rapidly evolving into a unified ecosystem of connected, intelligent, real-time operations. Organizations are moving beyond automation alone they now demand visibility, orchestration, and data-driven predictability.

- Dec 01, 2025

In 2025, operational resilience has become the most discussed theme across manufacturing, logistics, and supply chain forums. From global disruptions to workforce variability and rising customer expectations, companies are racing to strengthen their ability to anticipate, absorb, and adapt to disruptions not merely react to them

- Nov 13, 2025

Unplanned downtime rarely starts with machine failure it starts with missing visibility. When assets aren’t where they should be, operations slow, workers wait, and productivity drops. This article shows how SyTrak turns reactive tracking into predictive visibility, using real-time location intelligence to prevent delays and eliminate operational surprises.

- October 30, 2025

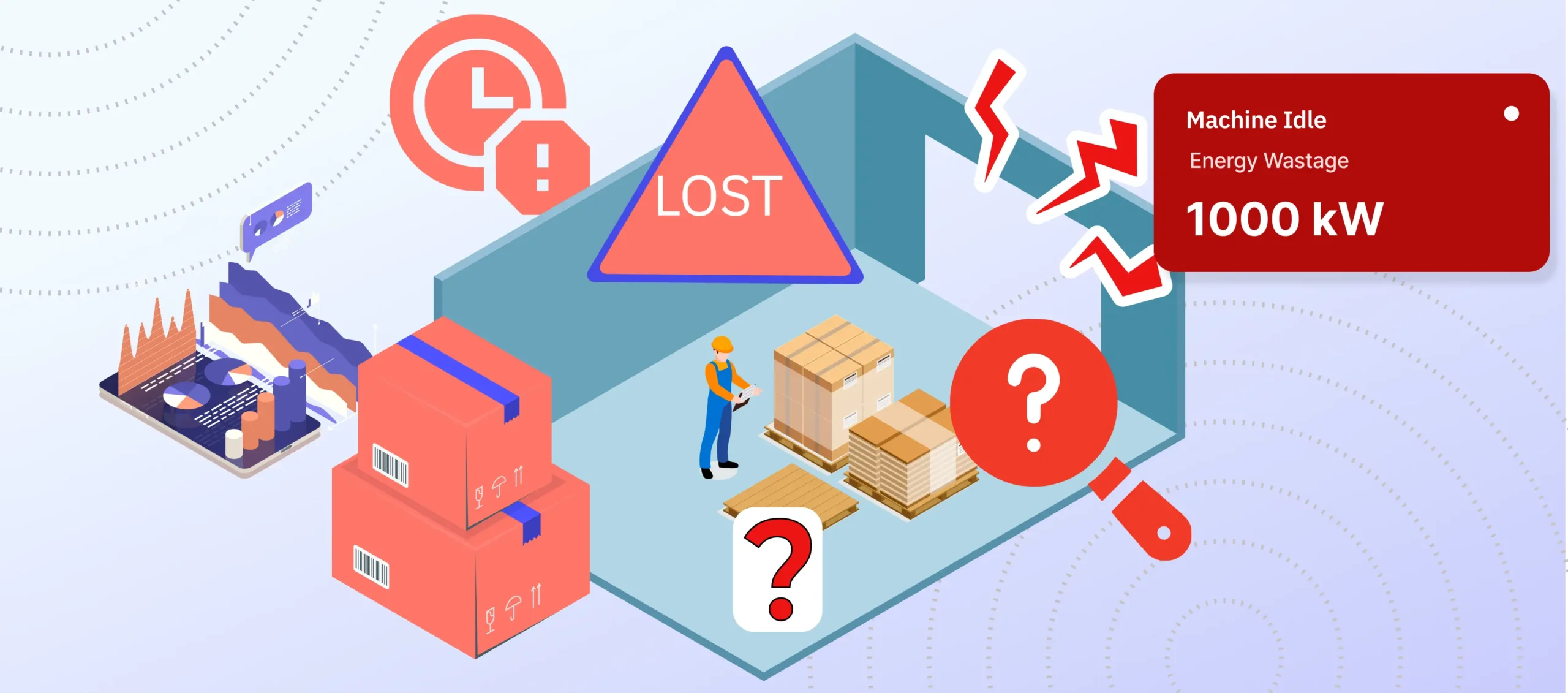

Manufacturing has always been defined by precision, efficiency, and control. But as the global industry transitions into the Industry 4.0 era, traditional systems are struggling to keep up with increasing operational complexity. Manual monitoring, disconnected systems, and reactive decision-making often lead to inefficiencies, production delays, and resource wastage.

- October 29, 2025

Factories today don’t just build products—they build possibilities. But as industries evolve, so do the challenges that define them. Production floors are more connected than ever, yet still fragmented. Data is abundant, yet insights remain buried. Efficiency goals are higher, but visibility across people, assets, and processes remains a constant struggle.

- October 06, 2025

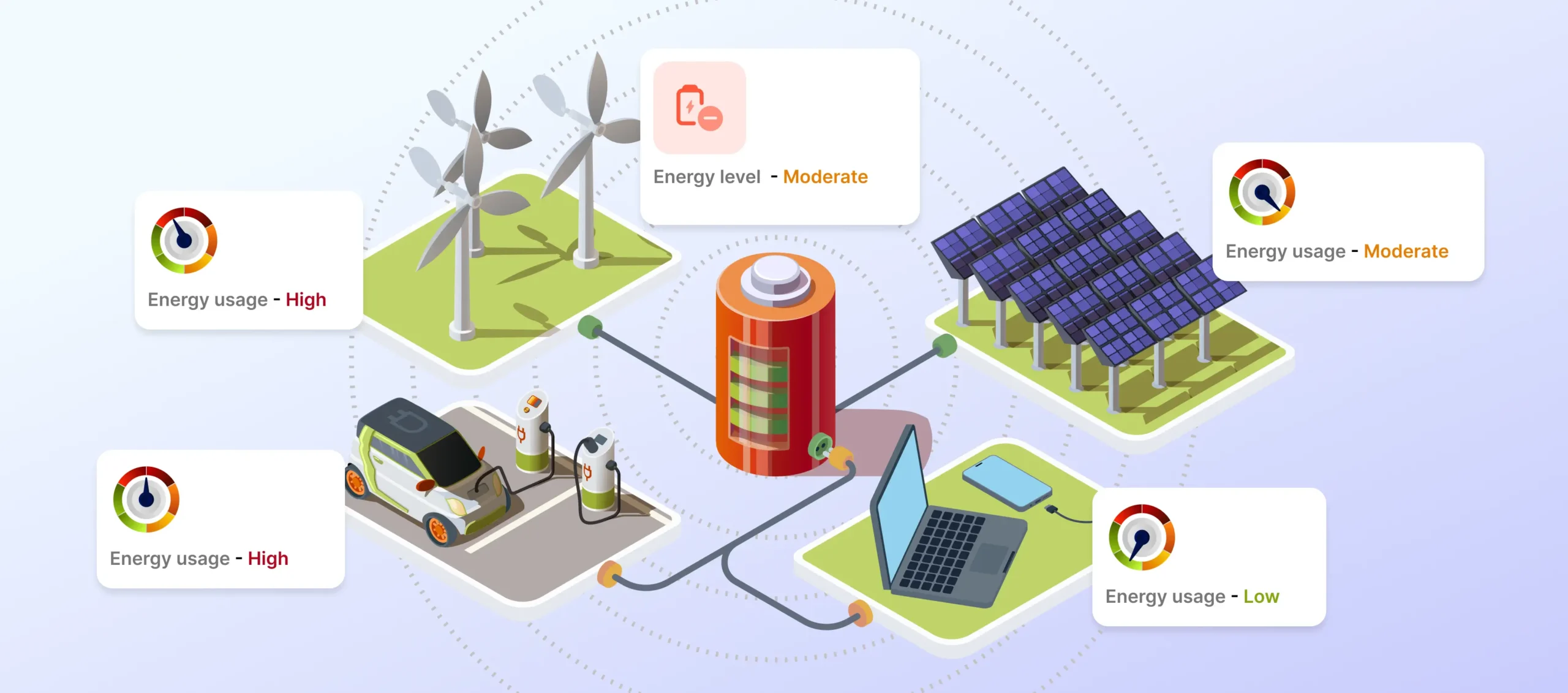

In an age where energy costs soar, sustainability is no longer just good practice—it’s a key competitive advantage. Yet many industrial operations still rely on outmoded systems: monthly or quarterly manual meter readings, delayed alerts about abnormal consumption, or generic reports that tell you what happened, not what to do.

- September 25, 2025

Manufacturing has always been about precision, efficiency, and control. Yet, in today’s Industry 4.0 era, traditional methods are struggling to keep pace with the complexities of modern production. Manual logs, static shift plans, and disconnected systems create blind spots that cost factories valuable time and resources. .

- September 18, 2025

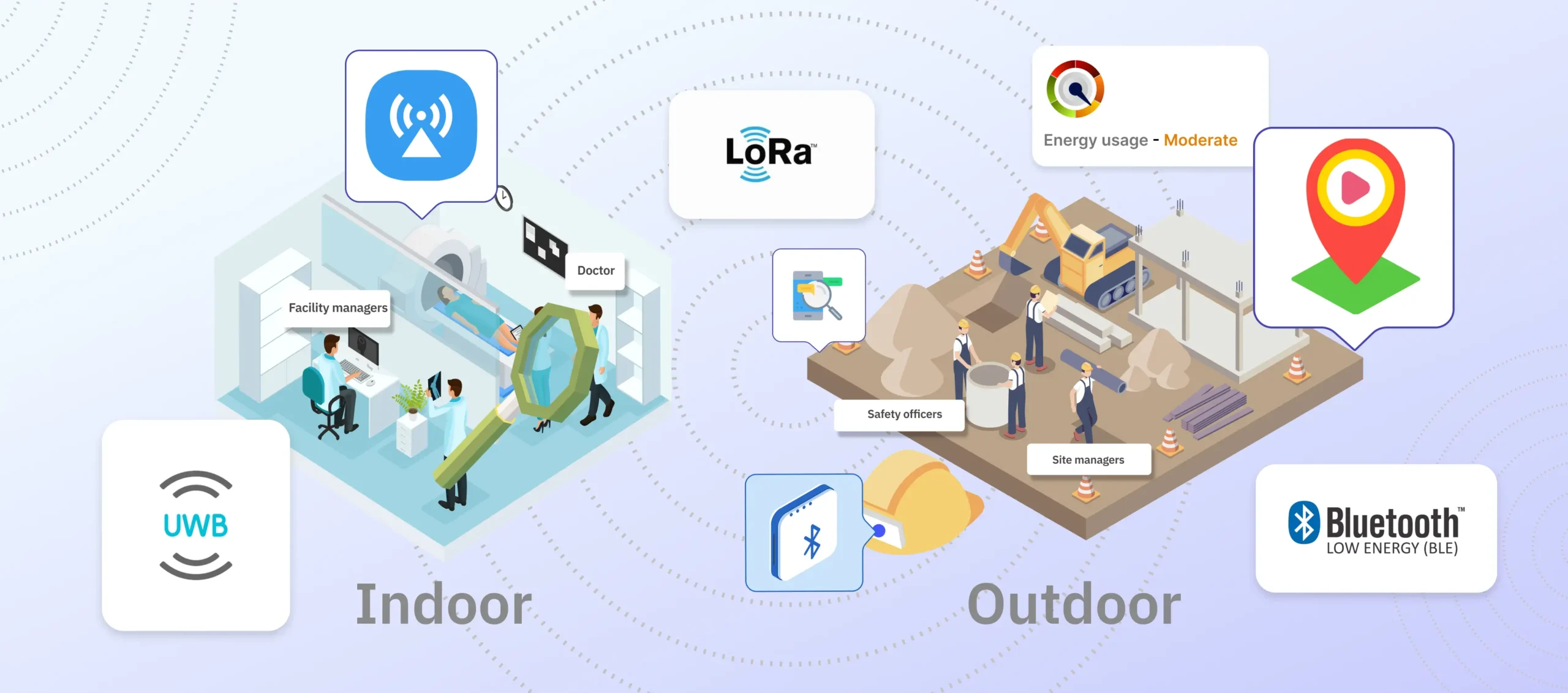

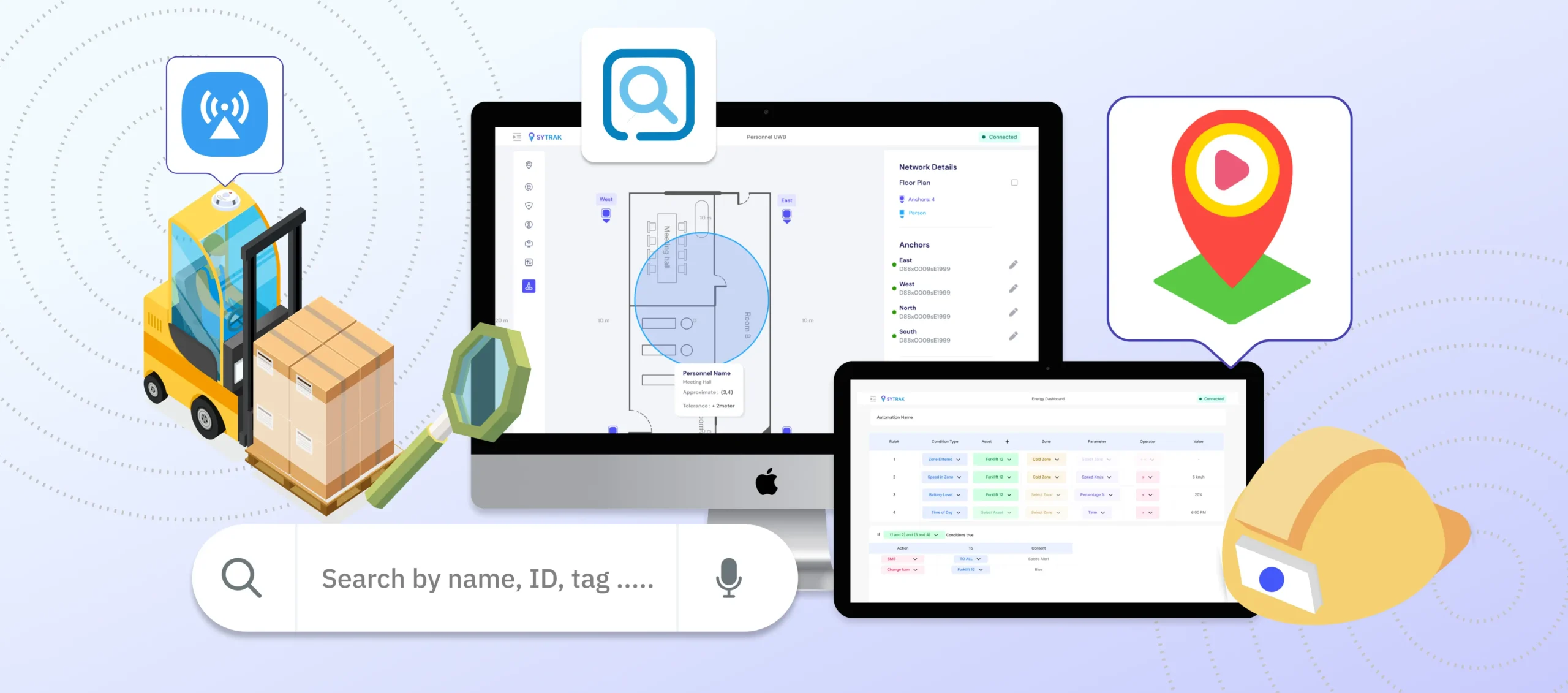

In today’s fast-paced Industry 4.0 landscape, companies can’t afford slow or disconnected asset management. From forklifts in warehouses to medical equipment in hospitals and machinery on construction sites, real-time visibility is essential. SYTRAK enables smarter tracking, monitoring, and decision-making to keep workflows agile, efficient, and secure across industries.

- September 10, 2025

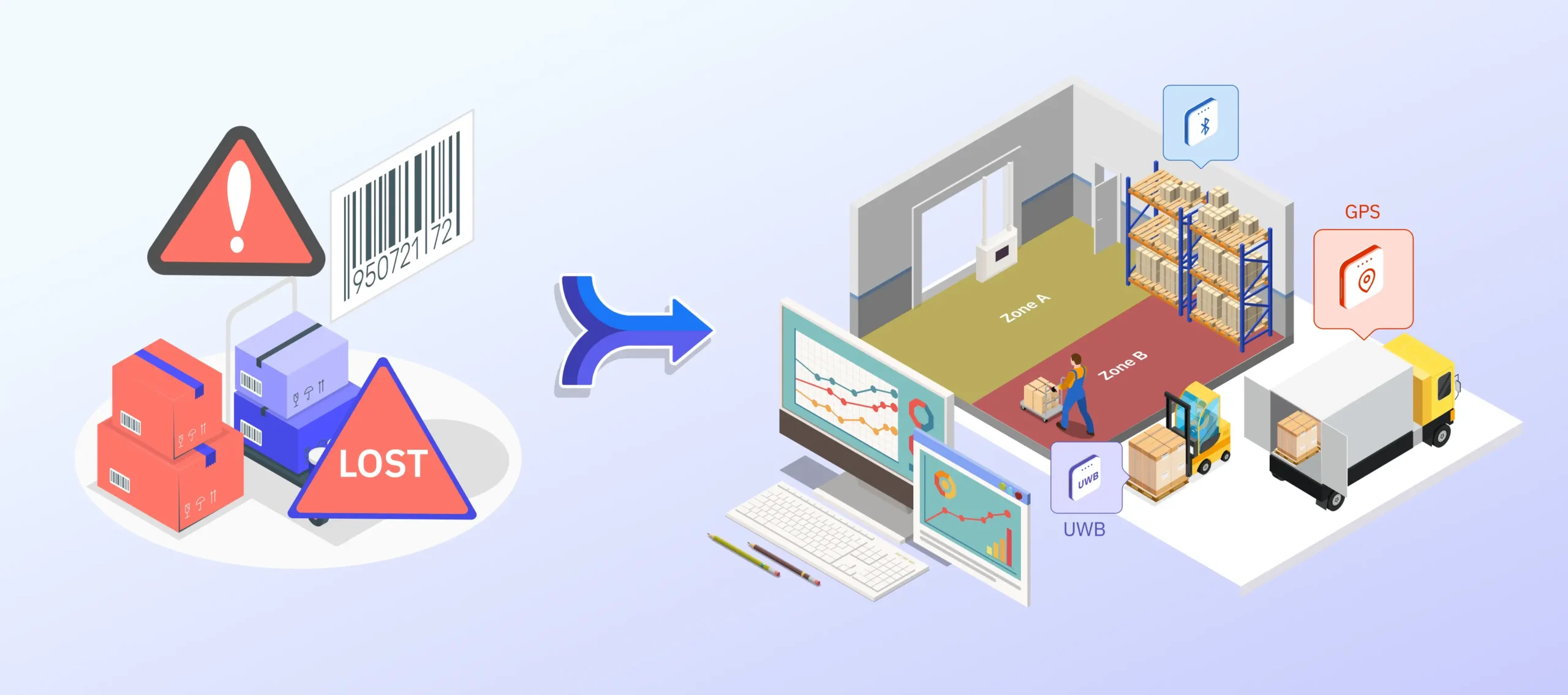

In an increasingly connected world, knowing where your assets are—and keeping them secure—is more critical than ever. Whether it’s a shipment in transit, a safety kit in a hospital, or a tool in a factory, SYTRAK ensures location intelligence with real-time visibility, helping industries respond faster, reduce risks, and stay in control.

- August 28, 2025

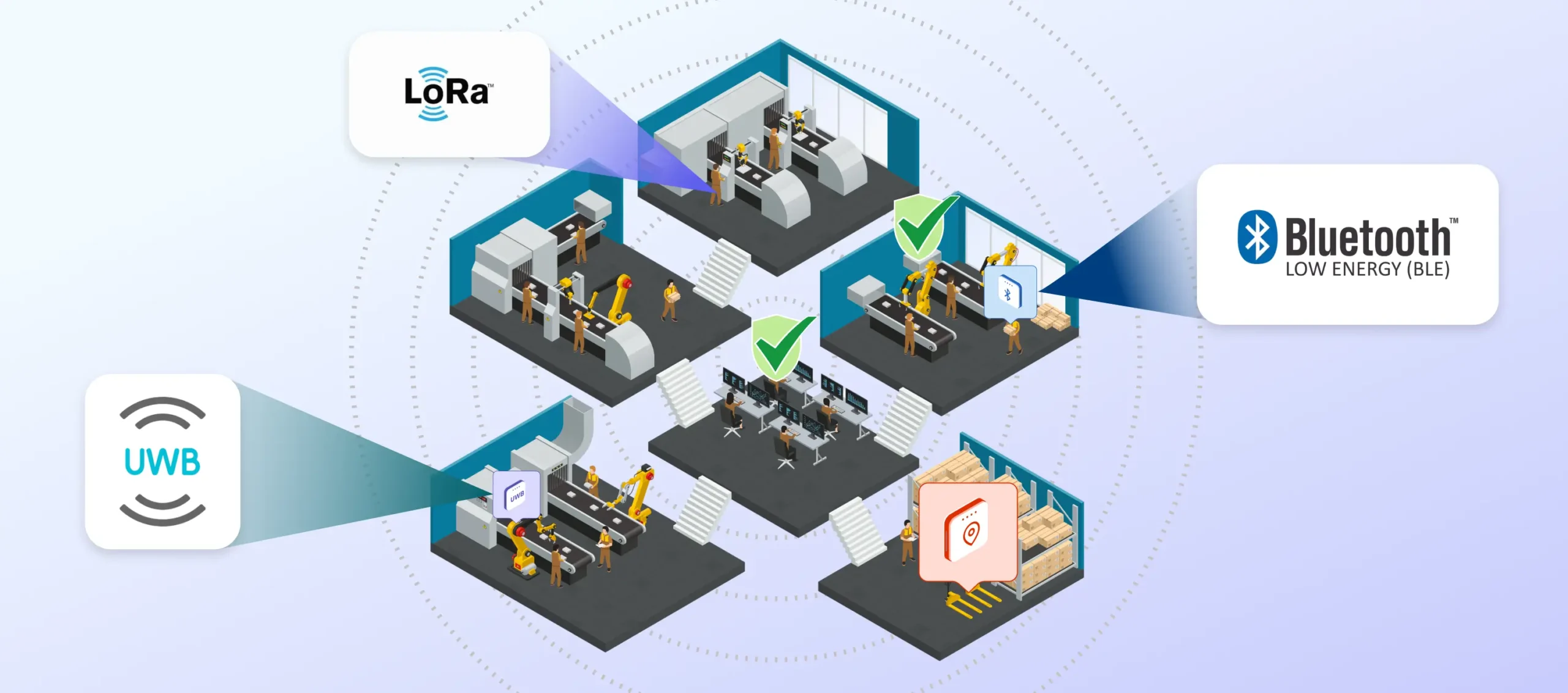

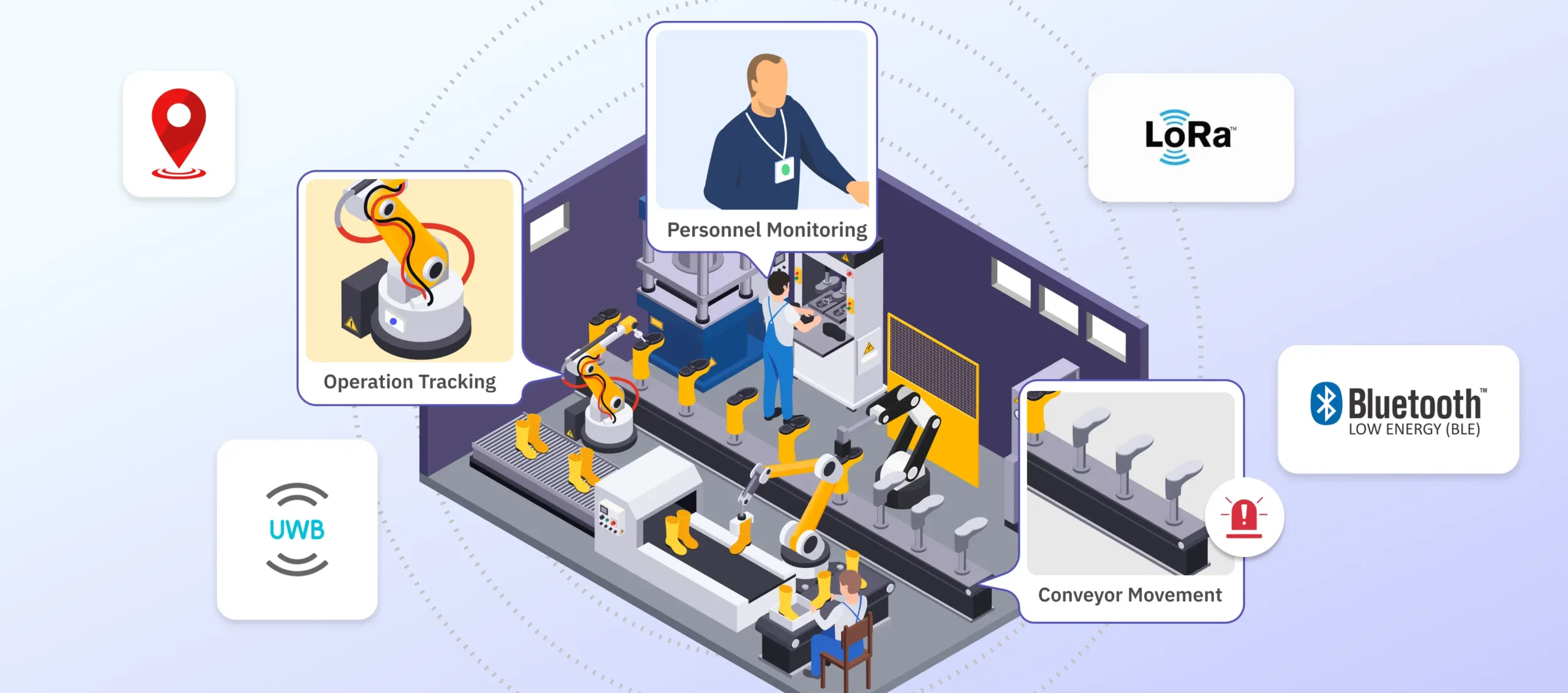

Manufacturing is a high-speed, high-stakes environment where multiple production lines operate at once. Machines, tools, materials, and workers must stay in sync for peak efficiency. With SYTRAK, manufacturers gain precise, real-time tracking of every moving part, reducing downtime, ensuring safety, and maintaining throughput in even the most complex industrial setups.

- August 8, 2025

In today’s fast-moving industrial world, simply knowing where assets are is no longer enough. What matters is understanding their context, purpose, and next step. SYTRAK delivers true orchestration by combining location data with analytics and predictive intelligence, turning visibility into active control. The result: smarter workflows, greater efficiency, and proactive operations.

- August 5, 2025

As industries evolve under Industry 4.0, asset tracking must deliver more than dots on a map. SYTRAK transforms tracking into orchestration, enabling safer, smarter, and more efficient operations. With contextual insights, intelligent coordination, and automation, SYTRAK empowers organizations to streamline workflows, reduce risks, and adapt quickly in even the most complex industrial environments.

- July 22, 2025

In a fast-paced, data-driven economy, real-time asset tracking is no longer optional — it’s essential. SYTRAK ensures you know where your tools, shipments, or equipment are at all times, while also delivering insights that reduce downtime, minimize losses, and boost productivity. Whether in hospitals, factories, or logistics, SYTRAK keeps critical operations secure and reliable.

Asset Tracking: The What & Why That Count.

- July 22, 2025

In a fast-paced, data-driven economy, real-time asset tracking is no longer optional — it’s essential. SYTRAK ensures you know where your tools, shipments, or equipment are at all times, while also delivering insights that reduce downtime, minimize losses, and boost productivity. Whether in hospitals, factories, or logistics, SYTRAK keeps critical operations secure and reliable.