Manufacturing has always been about precision, efficiency, and control. Yet, in today’s Industry 4.0 era, traditional methods are struggling to keep pace with the complexities of modern production. Manual logs, static shift plans, and disconnected systems create blind spots that cost factories valuable time and resources. To stay competitive, manufacturers need more than visibility—they need real-time asset tracking and intelligent orchestration. This is exactly where SyTrak makes the difference.

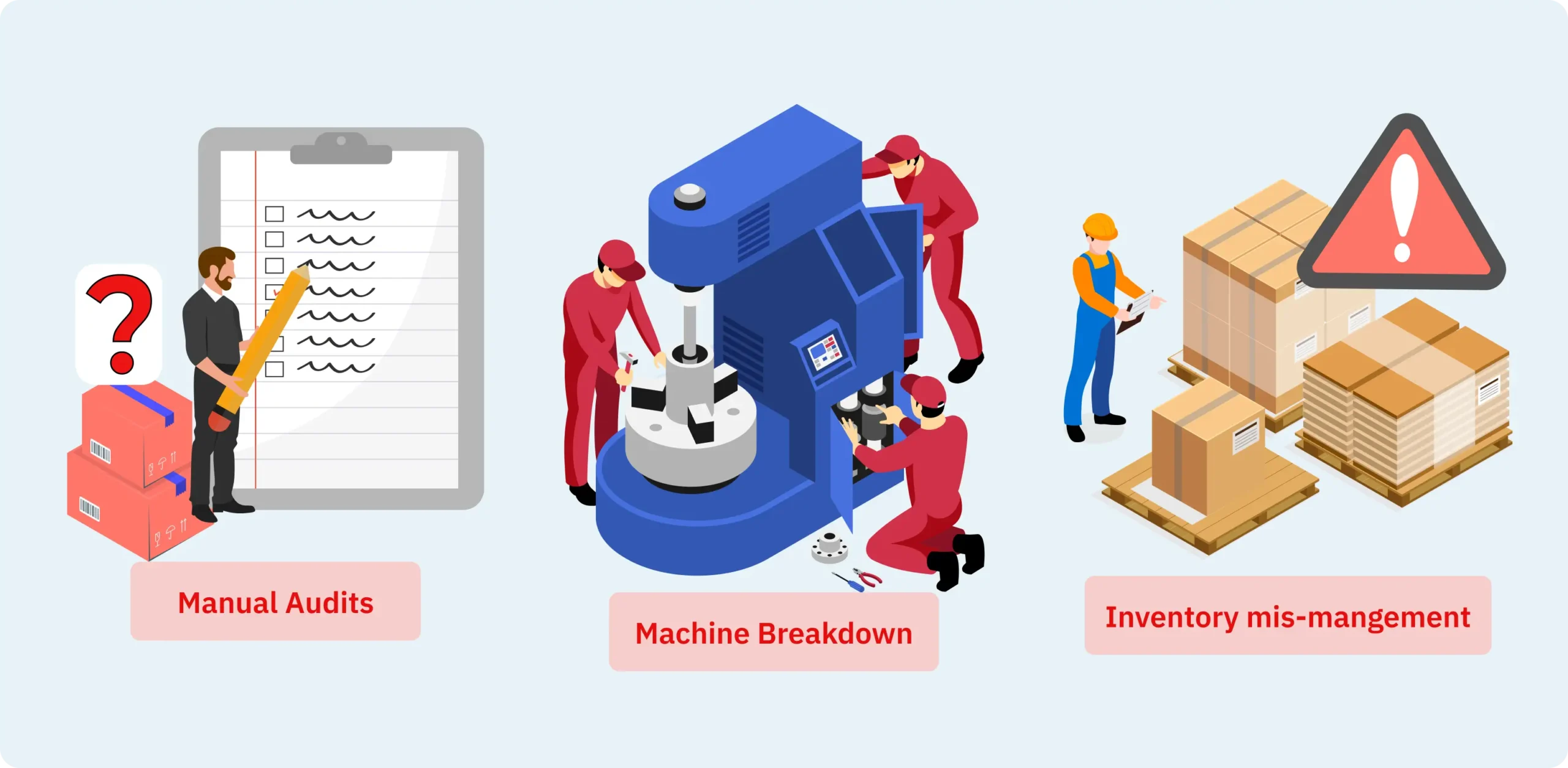

In most factories, challenges often arise not because people or machines underperform, but because processes lack synchronization. A sudden machine breakdown halts a production line. Workers wait for instructions while other departments are overburdened. Inventory arrives late or piles up in storage, throwing off schedules. These inefficiencies compound silently until they turn into downtime, wasted materials, or missed delivery deadlines. Relying on periodic audits or manual reporting only exposes problems after the fact, when the damage is already done.

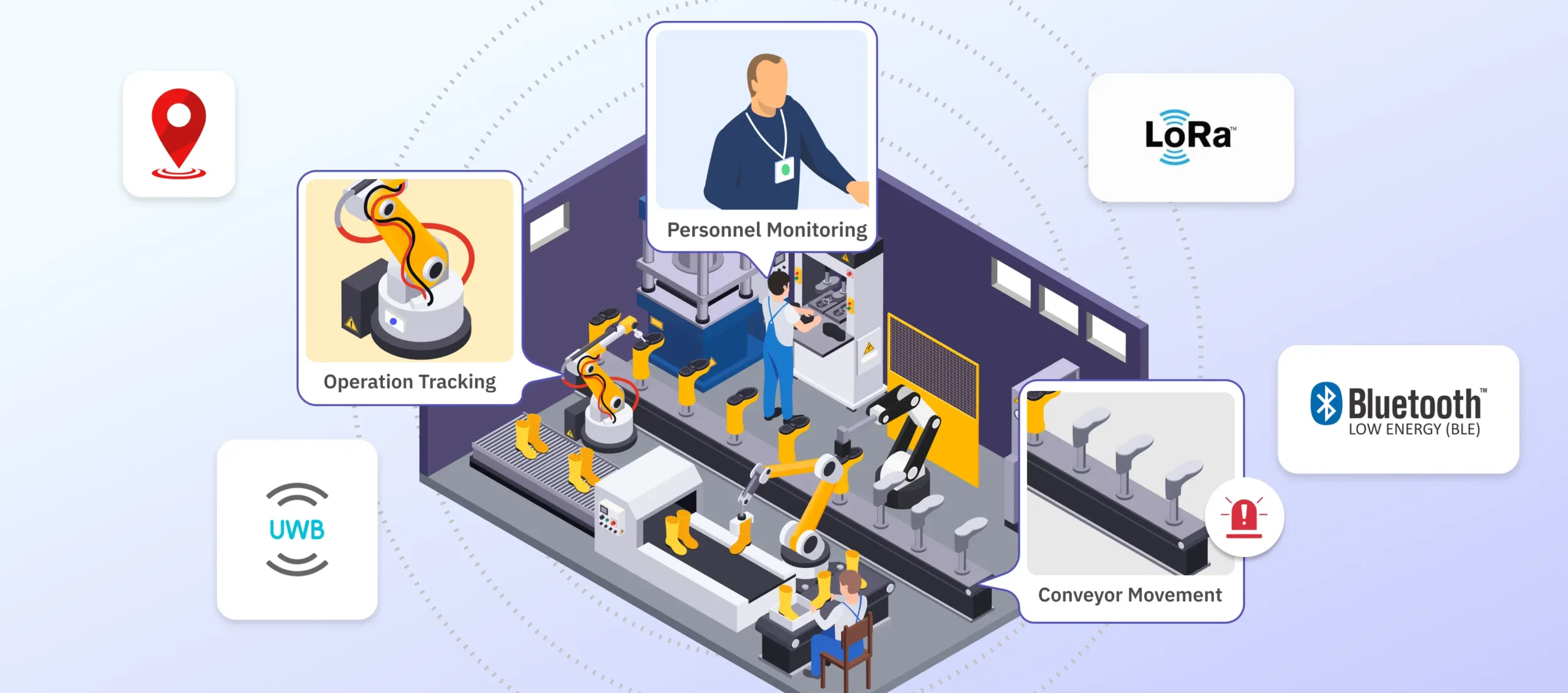

SyTrak was built to transform this outdated cycle. With real-time asset monitoring in manufacturing, every machine, tool, and process step becomes visible as it happens. Instead of waiting for problems to escalate, SyTrak alerts managers the moment anomalies occur—whether it’s equipment overuse, production slowdowns, or shifts in demand. This allows manufacturers to act proactively, not reactively.

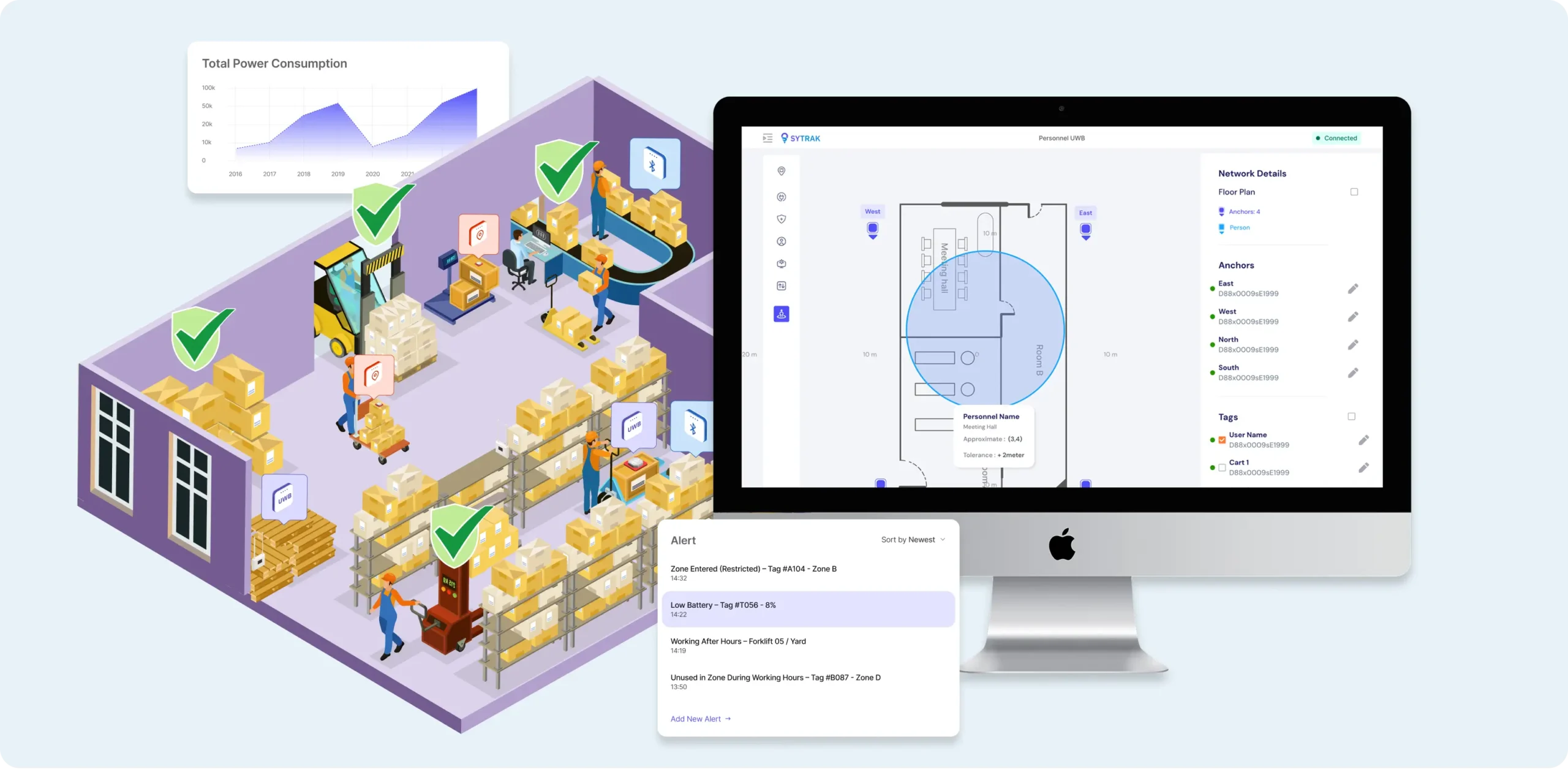

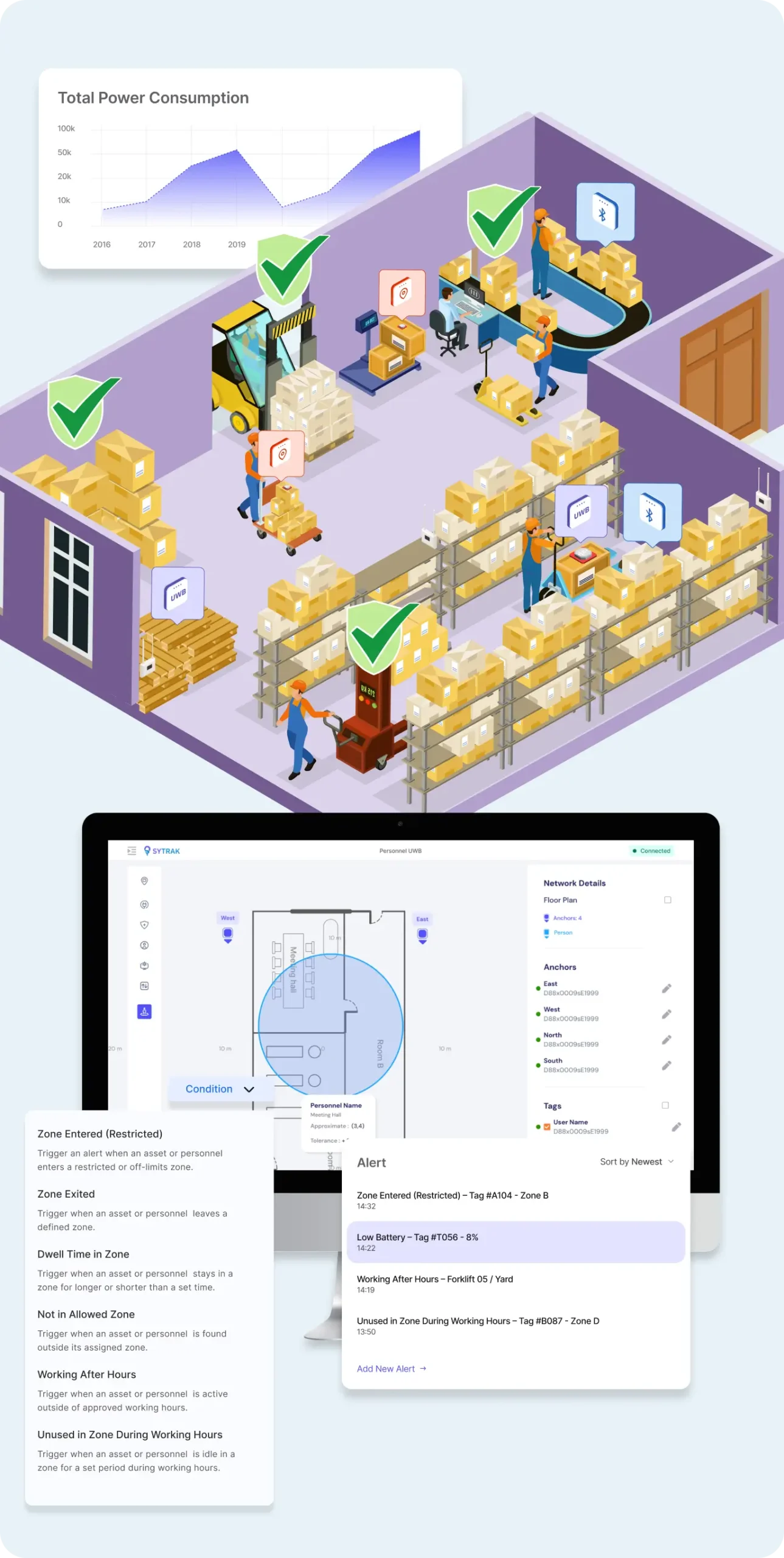

But SyTrak goes beyond tracking—it orchestrates. The platform integrates machine data, workforce availability, and supply chain updates into a centralized dashboard. This means supervisors can dynamically adjust shift allocations, rebalance workloads, or reschedule tasks instantly. Production bottlenecks are no longer discovered at the end of the day; they are identified and resolved in real time. The result is a factory that runs smoother, faster, and with fewer surprises.

The impact of this orchestration is tangible. Factories using SyTrak report reduced downtime, higher throughput, and significantly lower operational waste. Machines are maintained before they fail. Workers are deployed where they are needed most, avoiding both idle hours and unnecessary overtime. Raw materials flow into the production line exactly when required, keeping inventory lean but reliable. Above all, decision-makers gain full visibility from raw material intake to finished product delivery—something traditional systems simply cannot offer.

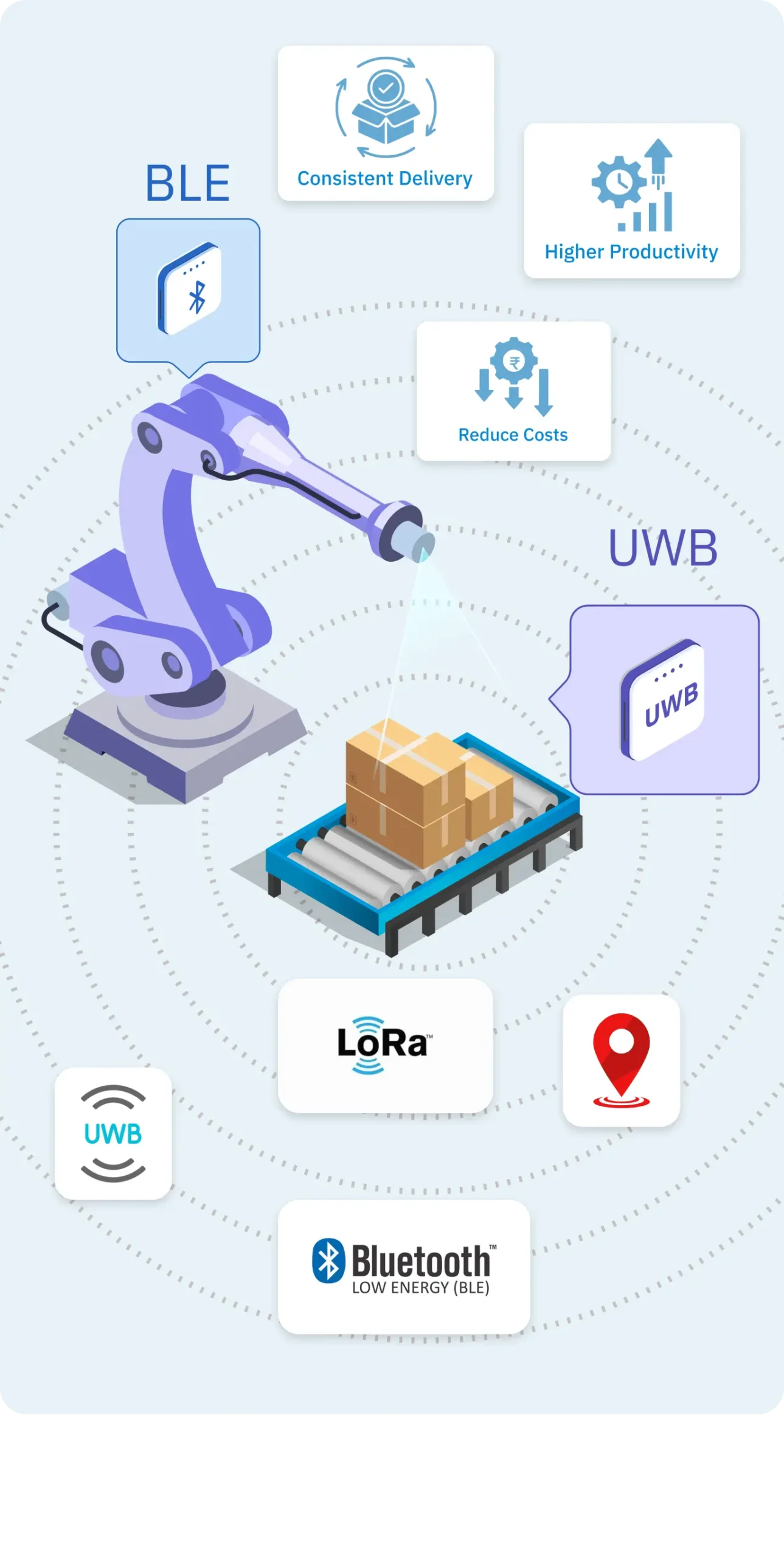

What makes SyTrak especially powerful is its alignment with Industry 4.0 manufacturing solutions. Modern factories are no longer isolated units; they are part of global supply chains that demand agility and speed. With SyTrak, manufacturers can synchronize with suppliers, respond quickly to changing orders, and maintain quality even under pressure. In an environment where customer expectations are rising and margins are tightening, this kind of responsiveness is what sets leaders apart from laggards.

The future of manufacturing lies in data-driven orchestration, not guesswork. By combining smart asset tracking with real-time decision-making, SyTrak enables factories to unlock higher productivity, reduce costs, and deliver consistent quality. Instead of firefighting problems, manufacturers can focus on continuous improvement and long-term growth.

For manufacturing leaders ready to embrace the next phase of operational excellence, the path forward is clear: move beyond outdated tracking methods and adopt a system that truly understands the rhythm of your factory. With SyTrak, you don’t just monitor assets—you orchestrate the entire operation. And in the world of Industry 4.0, that’s the key to staying ahead.