In an age where energy costs soar, sustainability is no longer just good practice—it’s a key competitive advantage. Yet many industrial operations still rely on outmoded systems: monthly or quarterly manual meter readings, delayed alerts about abnormal consumption, or generic reports that tell you what happened, not what to do. With SyTrak’s energy monitoring platform, you can transform blind energy usage into real-time intelligence—making every machine, process, and cycle count.

Most factories and manufacturing units face similar energy challenges. Idle machines consume power even when they’re not producing anything. Equipment inefficiencies go undetected until they become costly. Energy usage spikes get noticed too late. And reporting is manual, time-consuming, and often not granular enough for meaningful action. These issues lead to:

In short, without detailed visibility and timely insights, energy inefficiencies silently erode margins and environmental credentials.

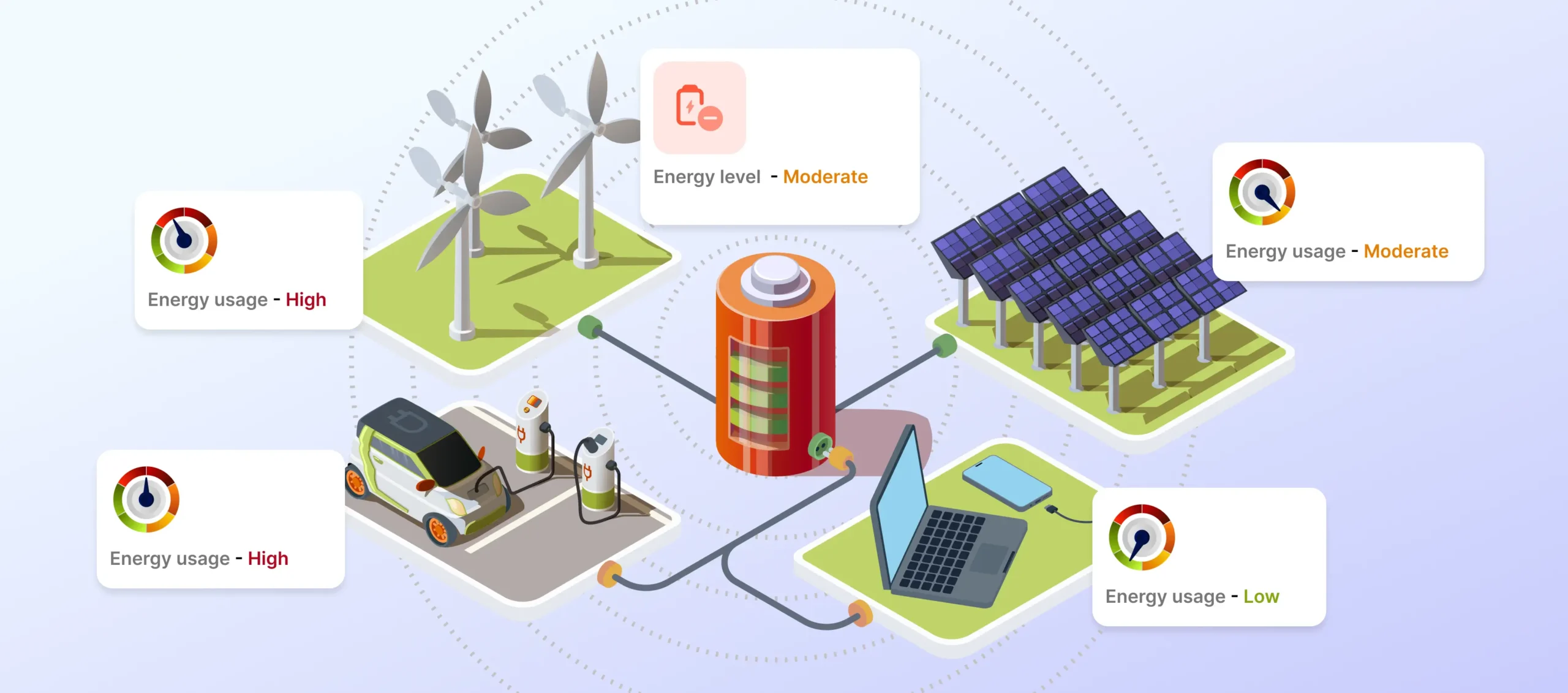

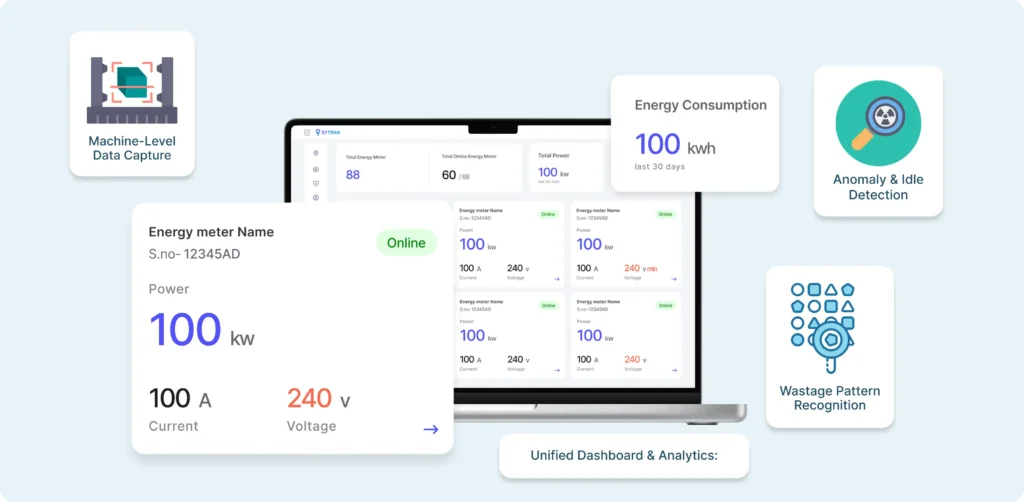

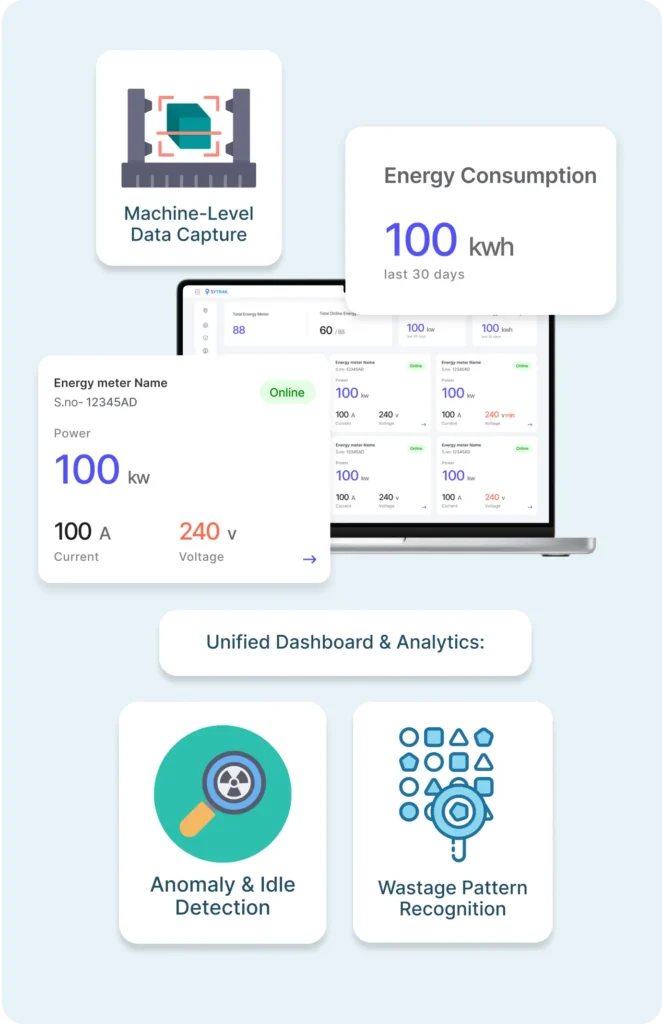

SyTrak’s energy monitoring solution addresses these pain points by delivering real-time, machine-level energy data. No more waiting to discover energy waste; anomalies are flagged instantly. Idle states are detected, usage patterns logged continuously, and insights delivered via a centralized dashboard that makes optimization visible and actionable.

Here are some of the core capabilities:

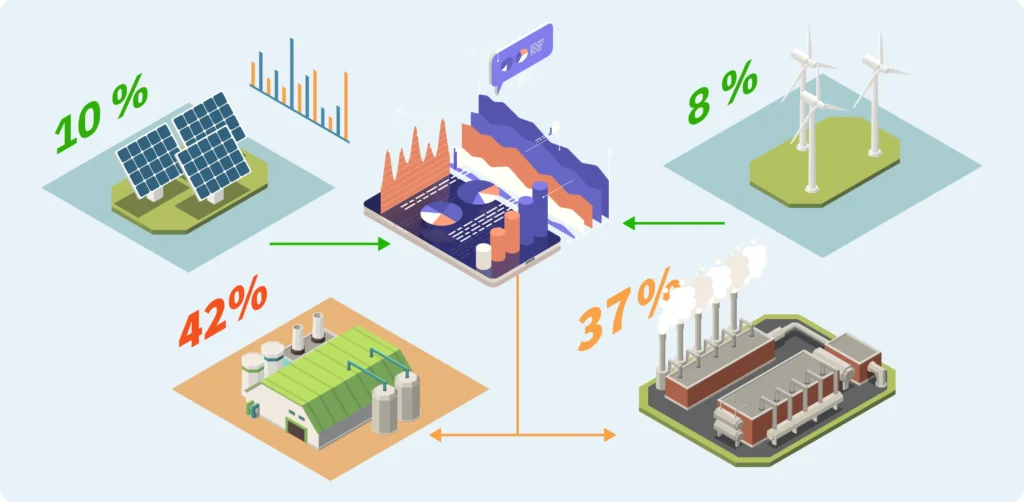

Adopting SyTrak’s system doesn’t just lead to cleaner metrics—it delivers real, measurable benefits. When factories move from analog, reactive energy tracking to SyTrak’s proactive platform, they commonly see:

Energy prices are volatile. Regulatory frameworks are tightening. Consumers and partners increasingly demand green credentials. For industrial operations, the risk of continuing with “business as usual” is no longer just financial—it’s reputational.

SyTrak gives you the tools to stay ahead: to monitor real energy consumption in real time, to detect and correct inefficiencies immediately, and to align operations with both cost-saving and sustainability goals.

If you’re ready to unlock energy intelligence:

In the transition toward smarter, more sustainable industrial operations, real-time energy monitoring is a foundational pillar. With SyTrak, you don’t just measure kilowatts—you gain insight, control, and the ability to act. Energy waste becomes visible. Problems are solved before they escalate. Operations become leaner, greener, and more profitable.

Don’t just track your energy—harness it with SyTrak.

Manufacturing has always been defined by precision, efficiency, and control. But as the global industry transitions into the Industry 4.0 era, traditional systems are struggling to keep up with increasing operational complexity. Manual monitoring, disconnected systems, and reactive decision-making often lead to inefficiencies, production delays, and resource wastage.

Factories today don’t just build products—they build possibilities. But as industries evolve, so do the challenges that define them. Production floors are more connected than ever, yet still fragmented. Data is abundant, yet insights remain buried. Efficiency goals are higher, but visibility across people, assets, and processes remains a constant struggle.

In a fast-paced, data-driven economy, real-time asset tracking is no longer optional — it’s essential. SYTRAK ensures you know where your tools, shipments, or equipment are at all times, while also delivering insights that reduce downtime, minimize losses, and boost productivity. Whether in hospitals, factories, or logistics, SYTRAK keeps critical operations secure and reliable.